Aluminium Extrusion Processes for CNC Machining

By:Admin

The new line of products features state-of-the-art CNC technology, allowing for the creation of complex and intricate designs with unparalleled accuracy. This level of precision is crucial for industries such as aerospace, automotive, and engineering, where the quality and reliability of aluminium extrusions are of utmost importance. The company's advanced manufacturing capabilities ensure that their products meet the highest standards and specifications, making them the preferred choice for demanding applications.

In addition to their cutting-edge technology, CNC Aluminium Extrusion also prides itself on its commitment to sustainability and environmental responsibility. The company utilizes advanced recycling and waste management processes to minimize its environmental impact, ensuring that their operations are as eco-friendly as possible. By prioritizing sustainability, the company not only fulfills its corporate social responsibility but also meets the evolving needs of environmentally conscious consumers and businesses.

Furthermore, CNC Aluminium Extrusion is dedicated to providing exceptional customer service and support. Their team of skilled professionals works closely with clients to understand their specific requirements and deliver tailored solutions to meet their unique needs. Whether it's a standard extrusion design or a custom project, the company's expertise and dedication to quality ensure that customers receive nothing but the best.

With a strong emphasis on research and development, CNC Aluminium Extrusion is constantly striving to push the boundaries of what is possible in the field of aluminium extrusion. Their commitment to innovation has led to the development of new and improved products that offer enhanced performance and versatility. By staying at the forefront of technological advancements, the company continues to set industry standards and raise the bar for excellence.

Incorporating advanced materials and manufacturing processes, CNC Aluminium Extrusion's products are engineered to deliver superior strength, durability, and performance. This makes them ideal for a wide array of applications, including structural components, heat sinks, framing systems, and more. The company's products offer unparalleled flexibility and adaptability, allowing for seamless integration into various designs and projects.

In addition to their technical capabilities, CNC Aluminium Extrusion takes pride in its rigorous quality control measures. Every step of the manufacturing process is carefully monitored and inspected to ensure that each product meets the highest standards of quality and consistency. This commitment to excellence is a testament to the company's unwavering dedication to delivering superior products that exceed customer expectations.

As CNC Aluminium Extrusion continues to expand its product offerings and market presence, the company remains steadfast in its commitment to innovation, quality, and customer satisfaction. With a proven track record of success and a reputation for excellence, the company is poised to lead the way in the aluminium extrusion industry for years to come. Their relentless pursuit of perfection and their unwavering dedication to pushing the boundaries of what is possible make them a trusted partner for businesses and industries seeking top-tier aluminium extrusion solutions.

Company News & Blog

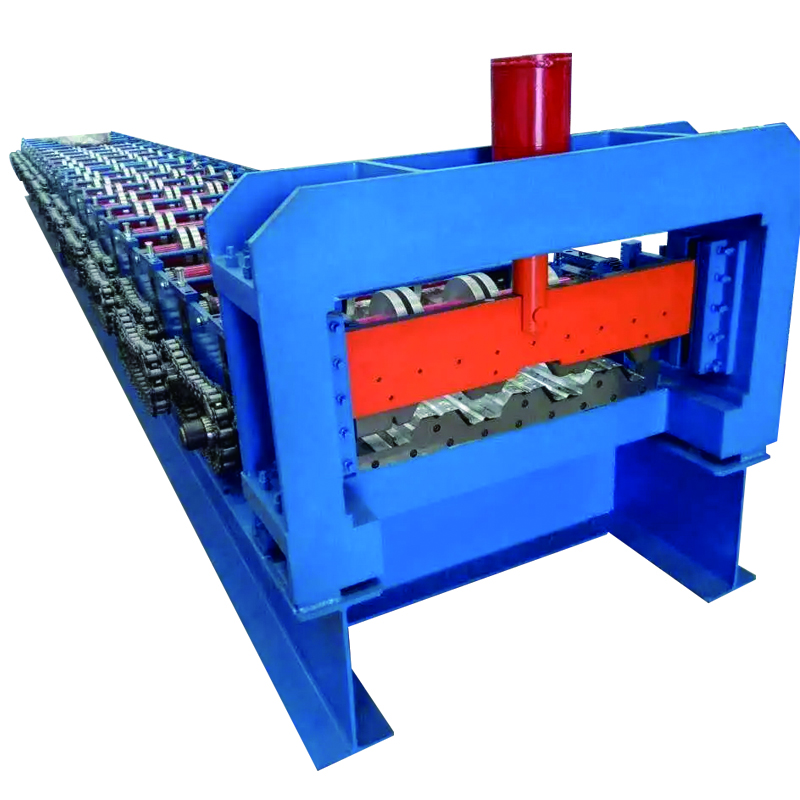

High-quality glazed tile roll forming and corrugating machine for sale

**Glazed Tile Roll Forming And Corrugating Machine Revolutionizing the Industry**In recent years, the construction industry has been witnessing a technological revolution, with advancements in machinery and automation paving the way for more efficient and precise construction processes. One such innovation making waves in the industry is the Glazed Tile Roll Forming And Corrugating Machine from {company name}. This revolutionary machine is set to transform the way glazed tiles are manufactured, offering a range of benefits to the construction industry.The Glazed Tile Roll Forming And Corrugating Machine is the latest offering from {company name}, a leading manufacturer of construction machinery and equipment. With years of experience and expertise in the industry, {company name} has earned a reputation for delivering high-quality, innovative solutions to meet the evolving needs of the construction sector.This state-of-the-art machine is designed to produce high-quality glazed tiles with precision and speed. Its advanced roll forming and corrugating technology ensures that the finished tiles are of superior quality, with consistent dimensions and a smooth glazed finish. This level of precision and quality control is unmatched in the industry, setting a new standard for glazed tile manufacturing.One of the key advantages of the Glazed Tile Roll Forming And Corrugating Machine is its ability to significantly increase production efficiency. With its automated processes and high-speed operation, the machine can produce a large volume of tiles in a short amount of time, thereby streamlining the manufacturing process and reducing production costs. This not only benefits manufacturers by improving their bottom line, but also has a positive impact on the overall supply chain, ensuring a steady and reliable source of glazed tiles for construction projects.Additionally, the machine’s versatility allows for the customization of tile dimensions and designs, catering to the specific requirements of different construction projects. This flexibility enables manufacturers to meet the diverse needs of their clients, while also allowing for creativity and innovation in tile design. By giving manufacturers the ability to produce a wide range of glazed tiles, all from one machine, {company name} is empowering the industry to expand its offerings and meet the demands of a dynamic construction market.Furthermore, the Glazed Tile Roll Forming And Corrugating Machine is designed with sustainability in mind. Its energy-efficient operation and minimal material wastage contribute to a greener manufacturing process, aligning with the growing emphasis on sustainable construction practices. By reducing energy consumption and minimizing waste, the machine not only benefits the environment, but also supports the construction industry’s commitment to sustainability and responsible resource management.As the construction industry continues to evolve and adapt to changing market demands, the Glazed Tile Roll Forming And Corrugating Machine is a prime example of the innovation driving this transformation. With its advanced technology, efficiency, and sustainability benefits, this machine is poised to revolutionize the production of glazed tiles, offering a new standard of quality, speed, and customization.In conclusion, the Glazed Tile Roll Forming And Corrugating Machine from {company name} represents a significant leap forward in the construction industry, providing manufacturers with the tools they need to meet the evolving demands of the market. With its precision, efficiency, versatility, and sustainability benefits, this machine is set to play a pivotal role in shaping the future of glazed tile manufacturing. As {company name} continues to lead the way with its innovative solutions, the construction industry can look forward to a new era of excellence in construction machinery and equipment.

High-Quality Glazed Steel Tile Roll Forming Machine - The Latest in Color Steel Technology

Color Steel Glazed Steel Tile Roll Forming Machine has been a game-changer in the roofing industry. This machine has revolutionized the process of producing glazed steel tiles, bringing a new level of efficiency and precision to the manufacturing process.The Color Steel Glazed Steel Tile Roll Forming Machine is a state-of-the-art piece of equipment that is designed to produce high-quality glazed steel tiles with ease. It is equipped with advanced technology and precision engineering, allowing for the seamless production of tiles that meet the highest standards of quality and durability.One of the key features of the Color Steel Glazed Steel Tile Roll Forming Machine is its ability to produce tiles with a wide range of colors and finishes. This allows for greater flexibility in design and customization, making it easier for manufacturers to meet the specific needs and preferences of their customers.In addition to its advanced technology, the Color Steel Glazed Steel Tile Roll Forming Machine is also designed for maximum efficiency. It is capable of producing tiles at a high rate of speed, allowing for increased production output and shorter lead times. This is a significant advantage for manufacturers looking to meet high demand and tight deadlines.Another notable feature of the Color Steel Glazed Steel Tile Roll Forming Machine is its user-friendly design. It is equipped with intuitive controls and a simple interface, making it easy for operators to set up and operate the machine with minimal training. This helps to streamline the production process and reduce the risk of errors or downtime.The Color Steel Glazed Steel Tile Roll Forming Machine is the product of years of research and development by [Company Name]. The company has a long history of innovation and excellence in the field of roofing and construction equipment, and the Color Steel Glazed Steel Tile Roll Forming Machine is a testament to their commitment to quality and innovation.[Company Name] is a leading manufacturer of roofing and construction equipment, with a strong reputation for delivering high-quality products that meet the needs of their customers. The Color Steel Glazed Steel Tile Roll Forming Machine is just one example of their dedication to advancing the industry and providing solutions that make a real impact.In addition to its focus on innovation, [Company Name] is also known for its exceptional customer service and support. The company works closely with its customers to understand their specific needs and goals, and then delivers tailored solutions that meet and exceed expectations. This commitment to customer satisfaction has helped [Company Name] build strong, long-lasting relationships with clients around the world.The Color Steel Glazed Steel Tile Roll Forming Machine is already making waves in the industry, and it is expected to have a significant impact on the way glazed steel tiles are manufactured. With its advanced technology, high efficiency, and user-friendly design, this machine is set to become a must-have for manufacturers looking to stay ahead of the curve in the competitive roofing market.Overall, the Color Steel Glazed Steel Tile Roll Forming Machine is a game-changer for the roofing industry. Its combination of advanced technology, efficiency, and user-friendly design sets a new standard for the production of glazed steel tiles. With the backing of [Company Name]'s expertise and dedication to excellence, this machine is poised to make a lasting impact on the industry and help manufacturers elevate their capabilities and offerings to meet the needs of their customers.

High-Quality Aluminum Coil Slitter for Efficient Metal Fabrication

Aluminum Coil Slitter Revolutionizes Production Processes at {}{}{}{}Aluminum is a widely used material in various industries due to its lightweight, durable, and corrosion-resistant properties. This versatile metal is a key component in the manufacturing of automotive parts, building materials, electronic devices, and packaging materials. To meet the increasing demand for aluminum products, {} has recently introduced a state-of-the-art Aluminum Coil Slitter, revolutionizing the production processes and setting new standards in the industry.The Aluminum Coil Slitter is a cutting-edge machine designed to precisely and efficiently slit aluminum coils into narrower widths, meeting the specific requirements of different applications. This advanced equipment is equipped with high-speed precision slitting knives, adjustable tension control, and advanced automation systems, allowing for unparalleled accuracy and consistency in the slitting process. This results in perfectly slit aluminum coils that are ready for further processing, contributing to enhanced productivity and cost-efficiency in the manufacturing process.With the installation of the Aluminum Coil Slitter, {} has further solidified its position as a leading manufacturer and supplier of high-quality aluminum products. The company prides itself on its commitment to innovation, continuous improvement, and customer satisfaction, and the addition of this cutting-edge slitting machine underscores its dedication to delivering excellence in every aspect of its operations.The introduction of the Aluminum Coil Slitter is a testament to {}'s continued investment in advanced technology and manufacturing capabilities. By incorporating the latest equipment and machinery into its production facilities, the company is able to stay ahead of the competition, streamline its processes, and meet the ever-evolving needs of its customers. This represents a significant milestone in {}'s journey towards becoming a preferred partner for clients seeking superior aluminum solutions.In addition to its technical capabilities, the Aluminum Coil Slitter is also a demonstration of {}'s strong commitment to sustainability and environmental responsibility. By optimizing the slitting process, minimizing material waste, and maximizing the utility of aluminum coils, the company is able to reduce its environmental footprint and contribute to a more sustainable manufacturing industry.The Aluminum Coil Slitter is poised to bring about a positive impact on the overall efficiency and performance of {}'s operations. By enhancing the precision and speed of the slitting process, the company can cater to a wider range of customer requirements, ensure faster turnaround times, and deliver tailored solutions that meet the highest standards of quality and accuracy.As {} continues to leverage cutting-edge technology and innovative solutions, the Aluminum Coil Slitter stands out as a prime example of the company's strategic approach to driving operational excellence and exceeding customer expectations. By empowering its production facilities with advanced machinery and equipment, {} is well-positioned to navigate the complexities of the modern manufacturing landscape and maintain its reputation as a reliable, forward-thinking aluminum solutions provider.In conclusion, the introduction of the Aluminum Coil Slitter marks a significant advancement in the capabilities of {}. This state-of-the-art machine represents a commitment to excellence, innovation, and sustainability, positioning {} as a leader in the aluminum industry. With its precision, efficiency, and environmental benefits, the Aluminum Coil Slitter is set to elevate the company's production processes and deliver superior outcomes for its customers.

High-Quality Roof Sheeting Machine: The Latest Technology for Efficient Roofing

Roof Sheeting Machine Revolutionizes the Construction IndustryThe construction industry is on the brink of a major transformation with the introduction of the latest innovation in roofing technology. The Roof Sheeting Machine, developed by a leading manufacturing company, is set to revolutionize the way roofs are made and installed.With a strong focus on quality, efficiency, and sustainability, the Roof Sheeting Machine is designed to produce high-quality metal roof sheets in a fraction of the time it takes using traditional methods. This cutting-edge technology is poised to significantly impact the construction industry by streamlining the roofing process and reducing costs.The Roof Sheeting Machine boasts a range of advanced features that set it apart from conventional roofing systems. One of its key strengths is its ability to produce custom-fit roof sheets, tailored to the specific dimensions and requirements of each individual project. This eliminates the need for on-site cutting and reduces material waste, making it an eco-friendly and cost-effective solution for builders and homeowners alike.In addition to its customization capabilities, the Roof Sheeting Machine is also designed for speed and efficiency. By automating the production process, it can churn out roof sheets at a rapid pace, allowing for faster installation and shorter project timelines. This not only benefits contractors by reducing labor costs and increasing productivity, but also minimizes disruption for homeowners during the construction process.Furthermore, the Roof Sheeting Machine is engineered for durability and longevity. With its precision engineering and high-quality materials, it is able to produce resilient and weather-resistant roof sheets that can withstand the harshest environmental conditions. This ensures that roofs made using this innovative technology will provide long-lasting protection for buildings and homes.The company behind the Roof Sheeting Machine has a strong track record of delivering cutting-edge solutions to the construction industry. With a commitment to innovation and excellence, they have established themselves as a leading provider of manufacturing equipment for the building and roofing sector. Their expertise and industry knowledge have been instrumental in the development of the Roof Sheeting Machine, positioning them at the forefront of the roofing technology market.The company's dedication to sustainability is also evident in the design and functionality of the Roof Sheeting Machine. By reducing material waste and improving energy efficiency, this technology aligns with the growing demand for environmentally conscious construction practices. As the construction industry continues to prioritize sustainability, the Roof Sheeting Machine represents a significant step forward in meeting these goals.As the demand for efficient and sustainable construction solutions continues to grow, the Roof Sheeting Machine is primed to become a game-changer in the roofing industry. Its advanced capabilities, cost-saving benefits, and environmental advantages make it a compelling choice for contractors, architects, and homeowners seeking a superior roofing solution.In conclusion, the Roof Sheeting Machine is a groundbreaking innovation that has the potential to transform the way roofs are made and installed. With its advanced features, customization options, and sustainability benefits, it is poised to revolutionize the construction industry and set a new standard for roofing technology. As the company continues to drive innovation and excellence, the Roof Sheeting Machine is set to leave a lasting impact on the future of construction.

Advanced Machine for Manufacturing Metal Steel Floor Webdeck with Roll Forming Technology

In the world of construction, commercial and industrial buildings require a strong foundation. And a solid floor deck is an integral part of laying the groundwork for any building's structure. In order to create a durable and robust floor deck, high-quality machines like the Floor Deck Roll Forming Machine are essential.Deck Floor Roll Forming Machines are designed to manufacture metal steel floor web decks. They are highly automated machines that can be customized according to specific requirements. The machine is used for producing metal floor decks of various design shapes and sizes. It makes it a crucial piece of equipment for the construction industry.One of the most significant advantages of the Roll Forming Machine is its versatility. It can produce metal decks with high precision and consistency, which cuts down waste and ensures quality control. Besides, you can quickly change the machine's settings to create different types of floor decks with varying thicknesses and sheet sizes.The Floor Deck Roll Forming Machine is also easy to operate, and it has a user-friendly interface. It comes with a control panel that makes it simple to set up the machine and adjust the speed. The machine is designed to produce decks at high speed, which enhances the productivity of the operation. The machine's efficiency is also boosted by its hydraulic system, which ensures stable and reliable performance.Additionally, the CZ Purlin Machine is ideal for producing metal floor decks with profiles for light steel framing. It has the capability of producing C and Z-shaped profiles that are commonly used for roof and wall framing. The machine has a simple and easy-to-use adjustment system that allows operators to tweak the profile's shape and size for different applications.In conclusion, the Floor Deck Roll Forming Machine is a must-have equipment for any construction or manufacturing company. It offers versatility, precision and consistency, which translates to quality products. It also has an efficient design, user-friendly interface and hydraulic system for high productivity. It's worth noting that manufacturers should limit themselves to remove brand names during promotions. So, if you're looking to produce metal floor decks for your construction projects, consider investing in a high-quality Roll Forming Machine.

High-quality Steel Roofing Sheet Roof Tile Forming Machine: A Reliable Solution for 0.6mm 1219mm Sheets

Title: High-Quality Steel Roofing Sheet Roof Tile Forming Machine Now Available in ChinaIntroduction:China has become a global leader in manufacturing machinery and equipment, offering cutting-edge solutions for a wide range of industries. Adding to its repertoire is the introduction of a high-quality 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine. Produced by a renowned Chinese manufacturer, this machine promises to revolutionize the roofing industry with its superior performance and durability.Advancements in technology have significantly contributed to the development of more efficient roofing solutions. The new 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine offers exceptional features that ensure the production of top-notch roofing tiles. With strict quality control measures in place, this advanced machinery is proving to be a game-changer in the field of cold roll forming.Product Features:The 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine boasts an array of impressive features that set it apart from other machines in the market. Let's take a closer look:1. Robust Construction: The machine is manufactured using high-quality materials, ensuring durability and reliability in its performance. Its sturdy frame and components make it a long-lasting asset in any manufacturing setup.2. Precision Engineering: This machine utilizes advanced technology to ensure precision and accuracy in the production of roofing tiles. Every detail is meticulously crafted, resulting in consistent and uniform tiles that meet the highest industry standards.3. Efficient Production: Equipped with a powerful motor, the machine operates at optimal speeds, enabling high-volume production without compromising on quality. Its automated processes reduce manual labor and increase efficiency, minimizing production time and costs.4. Versatility: The machine is designed to work with a wide range of materials, including steel, to produce various types of roofing tiles. This versatility allows manufacturers to cater to different consumer demands, expanding their market reach.5. User-Friendly Interface: The machine's user-friendly interface ensures easy operation, even for those with minimal experience in roll forming. Its intuitive controls and clear instructions make it accessible to a broader range of users, accelerating production and minimizing errors.Company Introduction:The 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine is manufactured by a prominent Chinese company well-known for its expertise in sheet roll forming machinery. With years of experience and a commitment to excellence, this manufacturer has established itself as a reliable and trusted provider of innovative machinery solutions.The company's state-of-the-art manufacturing facility and skilled workforce enable the production of high-quality machines that meet global standards. Along with the 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine, they offer a comprehensive range of sheet roll forming machines tailored to various industries.Conclusion:The introduction of the high-quality 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine from China marks a significant advancement in the roofing industry. With its robust construction, precision engineering, efficient production capabilities, and user-friendly interface, this machine empowers manufacturers to produce superior-quality roofing tiles with ease.As China continues to lead in technological advancements, this latest offering further strengthens its position as a global powerhouse in machinery manufacturing. Manufacturers worldwide can now benefit from this excellent roofing sheet roll forming machine, ensuring increased productivity, improved product quality, and ultimately, enhanced customer satisfaction.

High-Quality Automatic Slitting Machine for Efficient Production

Automatic Slitting Machine Revolutionizes Production ProcessIn the world of manufacturing, efficiency and precision are key factors in ensuring the highest quality products are produced in a timely manner. Recently, a groundbreaking new technology has emerged that is set to revolutionize the production process for a wide range of industries. The Automatic Slitting Machine, developed by an innovative company, is poised to streamline production operations and increase output like never before.The Automatic Slitting Machine is a cutting-edge piece of equipment that is designed to accurately and efficiently cut various types of materials such as paper, plastic, and metal into precise widths. This state-of-the-art technology is equipped with advanced automation and precision cutting capabilities, making it an indispensable asset for companies looking to optimize their production processes.The company behind this groundbreaking machine is a leading manufacturer of industrial equipment with a strong focus on innovation and quality. With a proven track record of delivering cutting-edge solutions to a diverse range of industries, this company has established itself as a trusted partner for businesses looking to elevate their manufacturing processes.With a commitment to continuous improvement and a dedication to meeting the evolving needs of their customers, the company has invested heavily in research and development to bring the Automatic Slitting Machine to market. Through rigorous testing and refinement, they have developed a cutting-edge solution that is poised to set a new standard for precision cutting and automation in the manufacturing industry.One of the key features of the Automatic Slitting Machine is its advanced automation capabilities. This machine is equipped with cutting-edge technology that allows for seamless operation without the need for constant human intervention. This not only increases efficiency but also reduces the risk of errors that can occur with manual cutting processes, resulting in higher precision and consistency in the final product.Furthermore, the Automatic Slitting Machine is designed to handle a wide range of materials with ease. Whether it's paper, plastic, or metal, this versatile machine is capable of cutting these materials into precise widths with unmatched accuracy. This makes it an ideal solution for companies operating in diverse industries, from packaging and printing to electronics and automotive, and beyond.In addition to its automation and versatility, the Automatic Slitting Machine is also designed to maximize productivity. With its high-speed cutting capabilities and efficient operation, this machine can significantly increase output while reducing production time. This not only boosts efficiency but also enhances the overall profitability of the manufacturing process.The company has not only focused on developing cutting-edge technology but also on providing comprehensive support to their customers. From installation and training to ongoing maintenance and technical support, they are dedicated to ensuring that their customers are able to make the most of this groundbreaking machine in their production operations.As businesses across the manufacturing industry continue to seek ways to improve efficiency and drive innovation, the Automatic Slitting Machine is set to play a pivotal role in shaping the future of production processes. By leveraging advanced automation and precision cutting capabilities, this revolutionary technology is poised to empower companies with the tools they need to stay ahead in a rapidly evolving marketplace.In conclusion, the Automatic Slitting Machine represents a significant leap forward in the world of manufacturing technology. With its advanced automation, versatility, and ability to maximize productivity, this cutting-edge machine is set to revolutionize the production process for a wide range of industries. As the company behind this innovative technology continues to drive forward with their commitment to excellence, the future looks bright for businesses looking to elevate their manufacturing operations.

High-efficiency Slitting Line for Effective Metal Processing

Beijing, China - The modern world is fast-paced and ever-changing, therefore businesses around the globe need to adapt, evolve and innovate to remain competitive in the market. In China, there is a steel sheet manufacturing company that is doing just that. They are investing in a new piece of machinery - a CR slitting line - to meet the growing demand for high-quality, thin steel sheets.This company has been in the steel production industry for over two decades and has gained a reputation for delivering exceptional products and services to their clients. They are known for their commitment to quality, efficiency, and customer satisfaction. Their decision to invest in a cutting-edge CR slitting line is another step in their relentless pursuit of excellence.The CR slitting line is a state-of-the-art machine designed to cut a coil of steel sheet into smaller, more manageable pieces, precisely and quickly. The CR (cold-rolled) slitting line is equipped with advanced technology, which allows it to cut at a much higher speed than traditional slitting machines, while maintaining precision and accuracy.This new equipment is vital to the company's expansion plans and growth strategy, as it enables them to produce thin, lightweight steel sheets - a product that is increasingly in demand in many different industries. The automotive and aerospace industries, for instance, require high-quality steel sheets that are both strong and lightweight, to improve fuel efficiency and other performance metrics. With the CR slitting line, this company can now produce these sheets more efficiently and cost-effectively.According to industry experts, the steel sheet manufacturing market is set to grow significantly in the next few years, as more companies require steel sheets for various applications. As such, the demand for high-quality, thin steel sheets will continue to rise. Therefore, this company's investment in the CR slitting line is not only timely but also strategic.In a statement, the company's CEO emphasized the importance of investing in the latest technologies to stay ahead of the competition. "Our customers are always looking for better quality products and faster delivery times. With the CR slitting line, we can meet those demands and exceed their expectations. We are committed to providing top-notch products and services to our clients, and this investment is proof of that commitment."The CR slitting line is not only beneficial to the company's operations but also the environment. The machine is designed to minimize waste, reduce energy consumption and produce steel sheets with consistent thickness. With the growing concern for global warming and environmental issues, the company's decision to invest in this equipment is commendable.The company's commitment to quality, efficiency, and customer satisfaction has earned them a loyal customer base, and the introduction of the CR slitting line will only serve to strengthen that relationship. With this equipment, they can deliver high-quality products faster, at a more competitive price point.In conclusion, the introduction of the CR slitting line by this steel sheet manufacturing company is a testament to their commitment to innovation and excellence. Their investment in this cutting-edge technology will not only benefit their operations but also their customers and the environment. As they continue to grow and expand their business globally, this equipment will play a vital role in their success.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.

High-Quality Aluminum Extrusion Milling Machine for Sale - Find Out More!

Aluminum Extrusion Milling Machine Revolutionizes Manufacturing IndustryIn an era characterized by technological advancements and innovations, the manufacturing industry is constantly seeking new, efficient, and cost-effective solutions to improve production processes. The introduction of the groundbreaking Aluminum Extrusion Milling Machine by {Company Name} has taken the industry by storm, offering a cutting-edge solution to aluminum extrusion milling with unparalleled precision and efficiency.{Company Name} is a renowned leader in the manufacturing and distribution of industrial machinery, offering a wide range of high-quality equipment designed to meet the diverse needs of the industry. With a strong emphasis on research and development, {Company Name} has consistently delivered state-of-the-art solutions that have garnered widespread recognition and acclaim.The Aluminum Extrusion Milling Machine is the latest addition to {Company Name}'s impressive portfolio, and it represents a significant advancement in the field of aluminum extrusion processing. The machine is equipped with advanced technologies and features that enable it to perform milling operations on aluminum extrusions with unmatched accuracy and speed, making it a game-changer for manufacturers in various sectors.One of the key highlights of the Aluminum Extrusion Milling Machine is its precision engineering, which allows for the seamless milling of complex shapes, profiles, and structures with minimal margin for error. This level of precision is critical in industries such as aerospace, automotive, and construction, where the quality and accuracy of aluminum components are paramount.Furthermore, the machine's high-speed milling capabilities significantly reduce production times, leading to greater efficiency and cost savings for manufacturers. By streamlining the milling process, {Company Name}'s Aluminum Extrusion Milling Machine enables companies to meet tight deadlines and production targets without compromising on quality.Another noteworthy feature of the Aluminum Extrusion Milling Machine is its versatility, as it can accommodate a wide range of aluminum extrusion profiles, sizes, and geometries. This versatility makes the machine an ideal solution for manufacturers with diverse milling requirements, allowing them to handle a variety of projects with ease and flexibility.In addition to its technical capabilities, the Aluminum Extrusion Milling Machine is also designed with user-friendly features that enhance ease of operation and maintenance. This attention to ergonomic design ensures that operators can maximize productivity while minimizing downtime and maintenance costs.The introduction of {Company Name}'s Aluminum Extrusion Milling Machine has generated significant interest and excitement within the manufacturing industry, with many companies expressing keen interest in adopting this cutting-edge technology. As the demand for high-quality, precision-milled aluminum components continues to grow, the machine is poised to play a pivotal role in meeting the evolving needs of the industry.In response to the overwhelming interest in the Aluminum Extrusion Milling Machine, {Company Name} has announced plans to offer comprehensive training and support services to help manufacturers integrate the technology seamlessly into their operations. This commitment to customer satisfaction underscores {Company Name}'s dedication to delivering not only advanced machinery but also value-added services that empower manufacturers to excel in a competitive market.With its unwavering commitment to innovation, quality, and customer satisfaction, {Company Name} has once again raised the bar for excellence in the manufacturing industry with the launch of the Aluminum Extrusion Milling Machine. As manufacturers continue to seek modern solutions that enhance productivity and precision, this groundbreaking technology is poised to usher in a new era of efficiency and performance in aluminum extrusion milling.