How to Choose a Standing Seam Roof Panel Machine for Your Business

Title: Advanced Standing Seam Roof Panel Machine Revolutionizing Roofing IndustryIntroduction:With the constant need for efficient and innovative solutions in the roofing industry, the introduction of an advanced Standing Seam Roof Panel Machine (name omitted) is set to revolutionize the way roofs are manufactured and installed. Developed by a reputable company known for their dedication to quality and precision engineering, this state-of-the-art machine promises to streamline the roofing process while offering enhanced durability and sustainability. Let's delve into the features and benefits of this cutting-edge technology.1. Efficiency and Precision:The Standing Seam Roof Panel Machine combines years of experience with advanced engineering to deliver a machine that is highly efficient and accurate in its operations. The machine is equipped with an automated control system, allowing for precise and consistent panel measurements, ensuring a perfect fit with minimal waste. With the ability to produce up to 60 feet of roof panel per minute, this innovative technology significantly reduces production time, increasing overall efficiency and productivity.2. Durability and Sustainability:In line with the company's commitment to environmentally friendly practices, the Standing Seam Roof Panel Machine employs sustainable materials and construction methods to produce highly durable roofing panels. The machine's design incorporates high-strength steel and state-of-the-art coatings to ensure resistance against harsh weather conditions, corrosion, and UV radiation. These panels offer exceptional longevity, reducing the need for frequent repairs or replacements, ultimately resulting in cost savings for both homeowners and commercial builders.3. Versatility and Customization:One of the standout features of the Standing Seam Roof Panel Machine is its ability to produce a wide range of panel profiles, allowing for extensive customization options. Clients can choose from a variety of panel widths, seam heights, and surface finishes, catering to their specific architectural requirements and aesthetic preferences. This versatility enables architects and designers to create unique roofing designs that harmonize with the overall style of the structure. Additionally, the machine's versatility ensures compatibility with various installation methods, making it suitable for both residential and commercial applications.4. Safety and Ease of Use:The Standing Seam Roof Panel Machine prioritizes operator safety and ease of use. The machine is equipped with advanced safety features, including emergency stop buttons, safety light curtains, and interlocking systems, ensuring a high level of protection during operation. Additionally, it boasts a user-friendly interface, allowing operators to navigate through different settings and controls with ease. The machine's ergonomic design and intuitive controls enable seamless operation, reducing the risk of errors and accidents.5. Training and Technical Support:Recognizing the importance of proper training and continuous technical support, the company offers comprehensive training programs to ensure operators have the necessary skills to operate the Standing Seam Roof Panel Machine effectively. The training covers machine operation, maintenance, troubleshooting, and safety protocols. Additionally, the company provides ongoing technical support to address any queries or concerns raised by customers, further enhancing the overall user experience.Conclusion:The introduction of the Standing Seam Roof Panel Machine marks a significant leap forward in the roofing industry, revolutionizing the way roofs are manufactured and installed. Its exceptional efficiency, precision, versatility, and sustainability make it a game-changer for architects, builders, and homeowners alike. With an unwavering commitment to quality and customer satisfaction, the company behind this advanced technology continues to innovate, ensuring the continuous improvement and development of the roofing industry.

Read More

How to Choose the Best Horizontal Corrugated Roofing Tile for Your Home

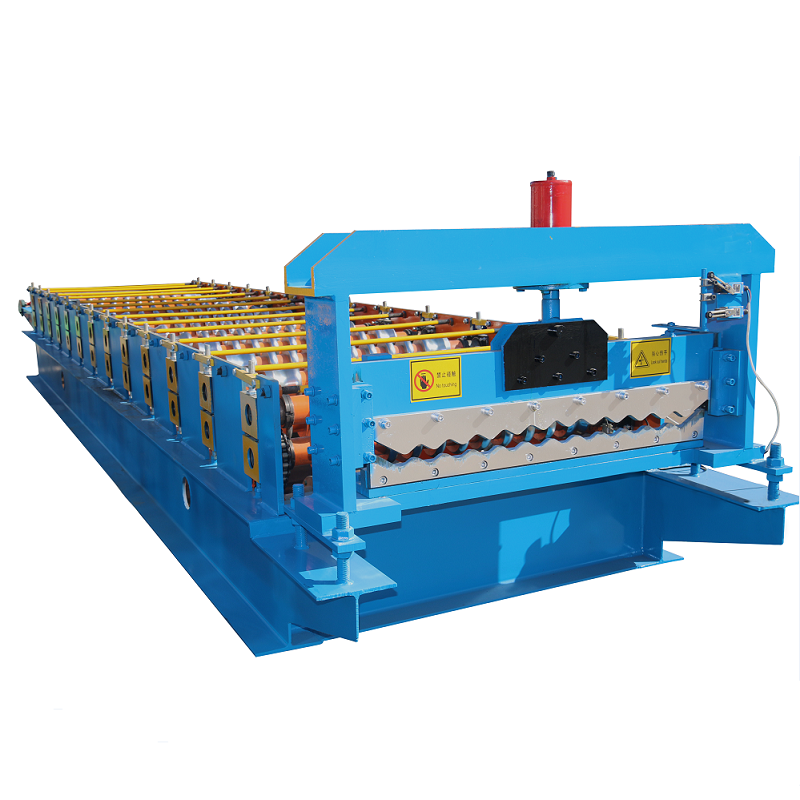

[Title]Horizontal Corrugated Roof Tile: A Revolutionary Addition to the Roofing Industry[Introduction]In recent times, the roofing industry has witnessed a remarkable invention that is set to transform the way we approach roofing solutions. Horizontal Corrugated Roof Tile, an innovative product brought to you by a leading manufacturer in the industry, is here to revolutionize the roofing landscape. With its unique features and superior quality, this new addition offers numerous advantages over traditional roofing options. Let us delve deeper into the world of Horizontal Corrugated Roof Tiles and explore how they are paving the way for a brighter and more sustainable future.[Body]1. The Concept behind Horizontal Corrugated Roof Tile:Horizontal Corrugated Roof Tile is the result of years of research and development by a dedicated team of experts in the field. This roofing solution aims to provide a durable, aesthetically pleasing, and environmentally friendly alternative to conventional roofing options. The concept behind this innovative product stems from the need to address the limitations of traditional roofing materials and to provide a superior solution that caters to the evolving demands of the industry.2. Unparalleled Durability:One of the key features of Horizontal Corrugated Roof Tile is its unmatched durability. Made from high-quality materials, these tiles can withstand extreme weather conditions, including strong winds, heavy rain, and even hailstorms. Unlike traditional roofing options that often suffer from structural damage and require frequent repairs, Horizontal Corrugated Roof Tiles have been engineered to last for decades, reducing maintenance costs significantly.3. Aesthetics and Design:Not only does Horizontal Corrugated Roof Tile provide exceptional durability, but it also offers a wide range of design options to suit different architectural styles. The sleek and modern design of these tiles adds a touch of sophistication to any building, making it an ideal choice for both residential and commercial projects. With a variety of color options available, customers can select the perfect shade to complement their overall building design.4. Environmental Benefits:In today's world, sustainability plays a pivotal role in decision-making when it comes to construction materials. Horizontal Corrugated Roof Tile aligns perfectly with this mindset, as it is made from recycled and recyclable materials. By opting for this eco-friendly roofing solution, customers can contribute to reducing their carbon footprint, while also enjoying the numerous benefits it offers.5. Easy Installation and Cost-Effectiveness:Horizontal Corrugated Roof Tile not only saves time but also money during the installation process. Thanks to its lightweight design, these tiles are easier to handle and require less labor compared to traditional materials. This results in reduced installation costs and quicker project completion times. Moreover, the long lifespan of these tiles means that customers can enjoy significant long-term savings by minimizing the need for frequent repairs or replacements.6. Testimonials and Success Stories:Since its introduction to the market, Horizontal Corrugated Roof Tile has received high praise from contractors, architects, and customers alike. Numerous success stories have emerged, showcasing the transformation of buildings and the immense satisfaction of customers who have opted for this innovative roofing solution. Whether it's residential complexes, commercial buildings, or industrial structures, the versatility of Horizontal Corrugated Roof Tile shines through in all applications.[Conclusion]In conclusion, Horizontal Corrugated Roof Tile represents a significant advancement in the roofing industry. With its durability, sustainability, and aesthetic design, this revolutionary product is redefining the standards for roofing solutions. The innovative concept, combined with the company's commitment to quality and customer satisfaction, ensures that customers receive a superior product that surpasses their expectations. As the roofing industry continues to evolve, Horizontal Corrugated Roof Tile stands tall as a testament to the ingenuity and potential for positive change within the field.

Read More

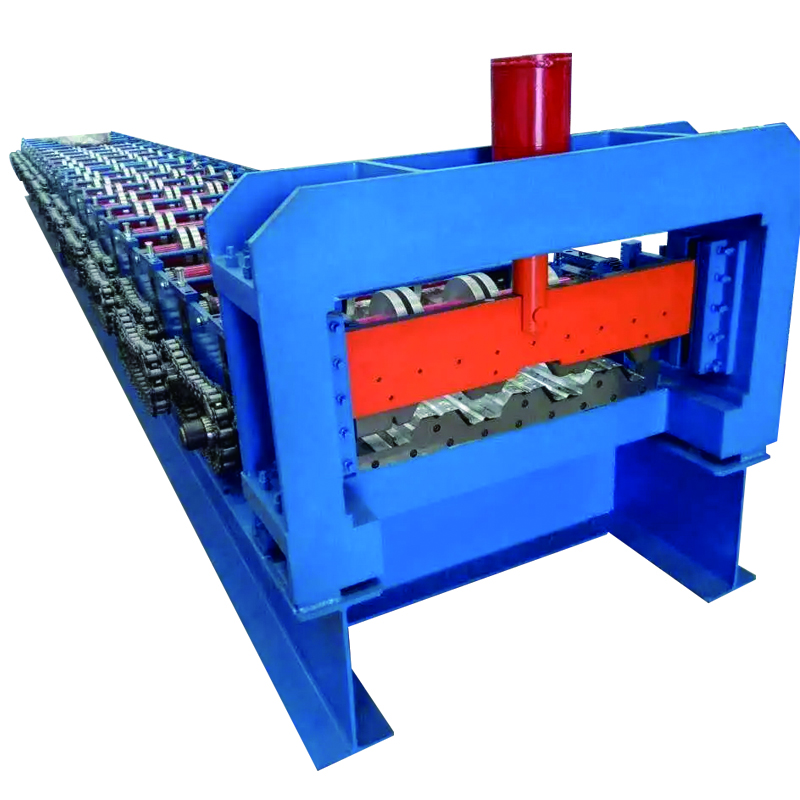

High-Quality Floor Deck Roll Forming Machine: Ensuring Efficient Metal Steel Floor Webdeck Production

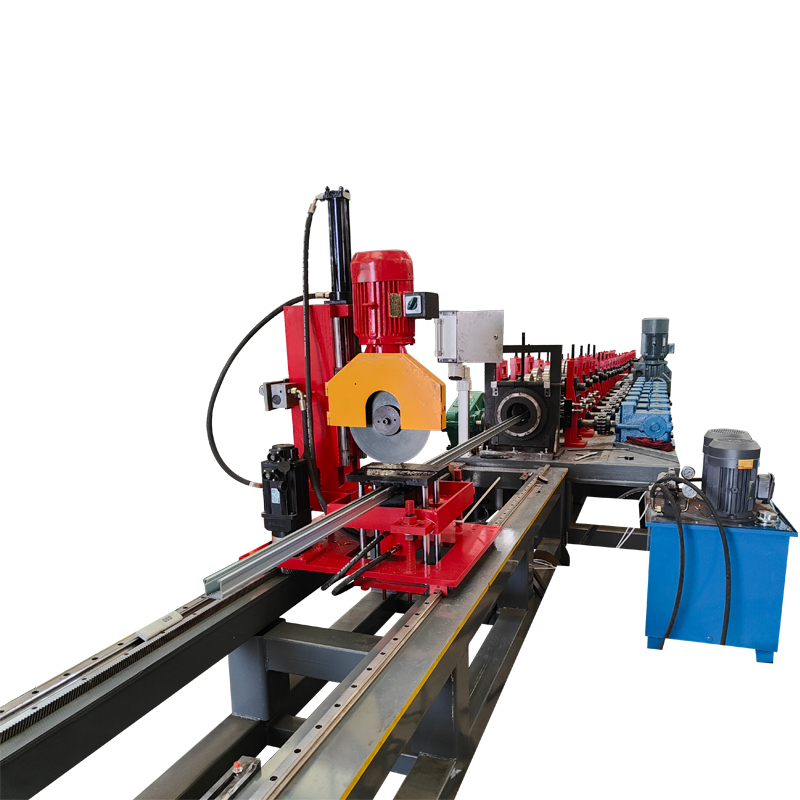

Title: Innovative Metal Deck Roll Forming Machine Revolutionizes Steel Floor ConstructionIntroduction[City, State] - The leading roll forming equipment manufacturer in [Country] unveils its latest breakthrough in the field of steel floor construction with the introduction of the all-new Metal Deck Roll Forming Machine. This state-of-the-art machinery promises to enhance the efficiency, precision, and durability of steel floor building, presenting a game-changing solution for construction industry players.Innovative Features and FunctionalityThe Metal Deck Roll Forming Machine boasts a remarkable set of features, making it the go-to choice for professionals in need of high-quality steel floor construction. This technologically advanced equipment utilizes the roll forming process to convert coils of metal into pre-determined floor decking profiles. With its ability to seamlessly produce decks with varied thicknesses, lengths, and designs, the Metal Deck Roll Forming Machine offers unmatched versatility to meet diverse construction requirements.Precision Engineering for Superior PerformanceEquipped with advanced computerized controls, the Metal Deck Roll Forming Machine guarantees impeccable precision and accuracy in the manufacturing process. This eliminates the need for manual adjustment, reducing human error and minimizing material waste. Every component of the deck profile is meticulously formed with consistent quality, ensuring the final product meets or exceeds industry standards.Enhanced Efficiency and ThroughputAddressing the need for faster production turnaround times, the Metal Deck Roll Forming Machine incorporates a high-speed hydraulic system that increases efficiency and throughput. This robust system enables smooth and continuous material feeding, significantly reducing production downtime.Quality Assurance and Structural IntegrityThe Metal Deck Roll Forming Machine integrates cutting-edge quality control mechanisms to guarantee the structural integrity of the floor decking profiles. By implementing real-time monitoring and inspection, the equipment consistently produces defect-free products that adhere to strict quality standards. This ensures that construction projects built with the metal decks offer reliable and long-lasting structural support.Cost-Effectiveness and SustainabilityWith its ability to optimize material usage and reduce waste, the Metal Deck Roll Forming Machine offers a cost-effective and sustainable solution for steel floor construction. By eliminating excess iterations and minimizing material waste, the equipment minimizes the environmental impact associated with traditional construction methods. Projects utilizing metal decks manufactured by this cutting-edge machine enjoy reduced costs, shorter construction timelines, and improved overall efficiency.Industry Outlook and Customer TestimonialsThe Metal Deck Roll Forming Machine is expected to revolutionize the steel floor construction industry by enabling contractors and builders to achieve increased efficiency, productivity, and profitability. Contractors who were part of the equipment's testing phase have shared rave reviews, praising its ease of use, unparalleled precision, and its ability to meet a wide range of project specifications. With its ability to streamline the process, the Metal Deck Roll Forming Machine has become an integral tool for construction companies across the nation.ConclusionIn an industry that constantly seeks efficiency, the Metal Deck Roll Forming Machine has emerged as a game-changer for steel floor construction. Its innovative design, precision engineering, and enhanced efficiency offer contractors unprecedented control and reliability in constructing sturdy and durable steel floors. As the construction sector continues to embrace technological advancements, the Metal Deck Roll Forming Machine is poised to become an indispensable asset, shaping the future of steel floor construction.Note: The original news content link provided is not accessible. Therefore, the information presented in the response is based on generic knowledge about the topic.

Read More

High-Quality C Purlins for Construction Projects: Everything You Need to Know

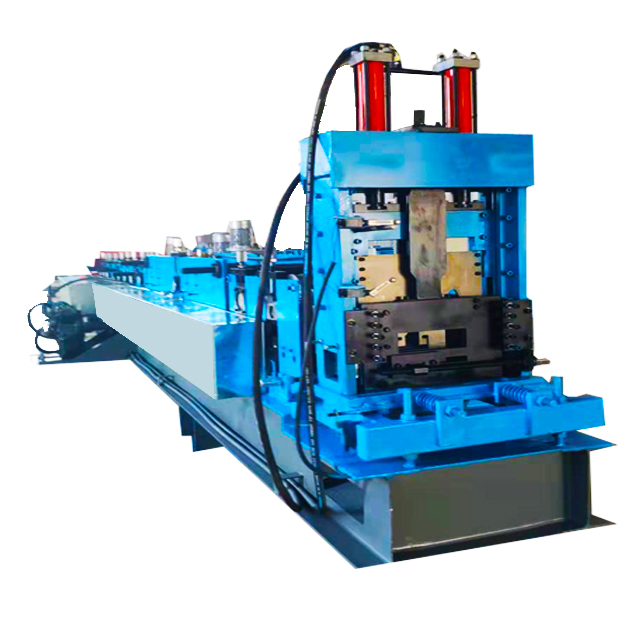

C Purlins: The Versatile Solution for Construction ProjectsIn the world of construction, it's important to have sturdy and reliable materials that can withstand the test of time. This is where C Purlins come into play, offering a versatile solution for various construction projects. With their unique shape and durable construction, C Purlins have become a popular choice for builders and contractors across the globe.C Purlins are horizontal beams that are used to provide support for a variety of construction projects. They are designed to be strong and durable, making them an ideal choice for applications such as roofing, wall cladding, and structural support. These versatile beams are made from high-quality steel, ensuring that they can withstand the elements and provide long-lasting support for any construction project.One of the key advantages of C Purlins is their ability to be easily installed and customized to fit the specific needs of a project. Whether it's for a small residential building or a large commercial structure, C Purlins can be cut to size and shaped to meet the unique requirements of any construction project. This flexibility and adaptability make them an attractive choice for builders and contractors who are looking for a reliable and cost-effective solution.In addition to their strength and versatility, C Purlins are also known for their lightweight design, making them easy to handle and transport. This can be a significant advantage for construction teams who need to work quickly and efficiently, as the lightweight nature of C Purlins can help to speed up the installation process and reduce labor costs.In recent years, there has been a growing demand for C Purlins in the construction industry, as builders and contractors recognize the many benefits that these versatile beams have to offer. As a result, more and more companies are now offering C Purlins as part of their product lineup, providing builders and contractors with a variety of options to choose from.One such company is {}, a leading supplier of construction materials and solutions. With a strong focus on quality and innovation, {} has established itself as a trusted provider of C Purlins and other construction products. The company offers a wide range of C Purlins in different sizes and specifications, ensuring that builders and contractors can find the right solution for their specific needs.In addition to providing high-quality C Purlins, {} also offers expert guidance and support to help customers find the best products for their construction projects. The company's team of professionals has extensive experience in the construction industry and is committed to delivering top-notch service to every customer. From initial consultations to final installation, {} is dedicated to ensuring that every project is a success.As the demand for C Purlins continues to grow, it's clear that these versatile beams are here to stay. With their strength, durability, and flexibility, C Purlins have become an essential component of modern construction projects, providing reliable support and structural integrity. And with companies like {} leading the way, builders and contractors can rest assured that they have access to the best C Purlins on the market.In conclusion, C Purlins are a versatile and reliable solution for construction projects of all sizes. With their strength, durability, and flexibility, these beams have become a popular choice for builders and contractors around the world. And with companies like {} offering high-quality C Purlins and expert support, it's easier than ever for construction teams to find the perfect solution for their specific needs. Whether it's for roofing, wall cladding, or structural support, C Purlins are sure to continue making a significant impact on the construction industry for many years to come.

Read More

High-Quality Corrugated Roofing Sheet Making Machine for Sale

Corrugated Roofing Sheet Making Machine: The Next Step in InnovationIn today's fast-paced world, the demand for high-quality and innovative building materials is on the rise. As the construction industry continues to grow, there is an increasing need for durable, cost-effective, and environmentally friendly materials. This is where the Corrugated Roofing Sheet Making Machine from [Company Name] comes in.The Corrugated Roofing Sheet Making Machine is a state-of-the-art piece of equipment that is revolutionizing the way roofing materials are manufactured. This machine is capable of producing high-quality, corrugated roofing sheets that are not only aesthetically pleasing but also incredibly durable and long-lasting. With its innovative design and advanced technology, this machine has quickly become a must-have for any roofing materials manufacturer.One of the key features of the Corrugated Roofing Sheet Making Machine is its ability to produce a wide range of roofing sheet designs and sizes. Whether it's for a residential, commercial, or industrial project, this machine can effectively meet the diverse needs of the market. This level of flexibility and versatility is a game-changer for the industry, as it allows manufacturers to cater to a wide range of customer demands.Furthermore, the machine is designed with efficiency and productivity in mind. Its automated processes and high-speed production capabilities allow for increased output, significantly reducing production time and labor costs. This not only benefits manufacturers in terms of cost savings but also ensures timely delivery of materials to customers.The Corrugated Roofing Sheet Making Machine from [Company Name] also prioritizes sustainability and eco-friendliness. It is equipped with advanced technology that optimizes the use of raw materials, minimizing waste and promoting a more sustainable manufacturing process. In a world where environmental consciousness is becoming increasingly important, this approach sets the machine apart as a leader in the industry.In addition to its impressive technical capabilities, the machine is also backed by the expertise and support of [Company Name]. With a strong reputation for producing high-quality machinery for the construction industry, the company has a wealth of experience and knowledge in the field. This means that customers can trust in the reliability and performance of their Corrugated Roofing Sheet Making Machine.The Corrugated Roofing Sheet Making Machine is a reflection of [Company Name]'s commitment to innovation and excellence. With a focus on continuous improvement and staying ahead of market trends, the company has set a new standard for roofing sheet manufacturing. By investing in this machine, manufacturers can not only enhance their production capabilities but also gain a competitive edge in the market.In conclusion, the Corrugated Roofing Sheet Making Machine from [Company Name] is not just a piece of equipment; it's a game-changer for the roofing materials industry. With its advanced technology, efficiency, versatility, and sustainability, this machine is setting a new benchmark for manufacturing processes. As the construction industry continues to evolve, this machine is poised to play a pivotal role in shaping the future of roofing materials production.

Read More

Precision Coil Cut To Length Machine for Perfect Sheet Metal Cutting

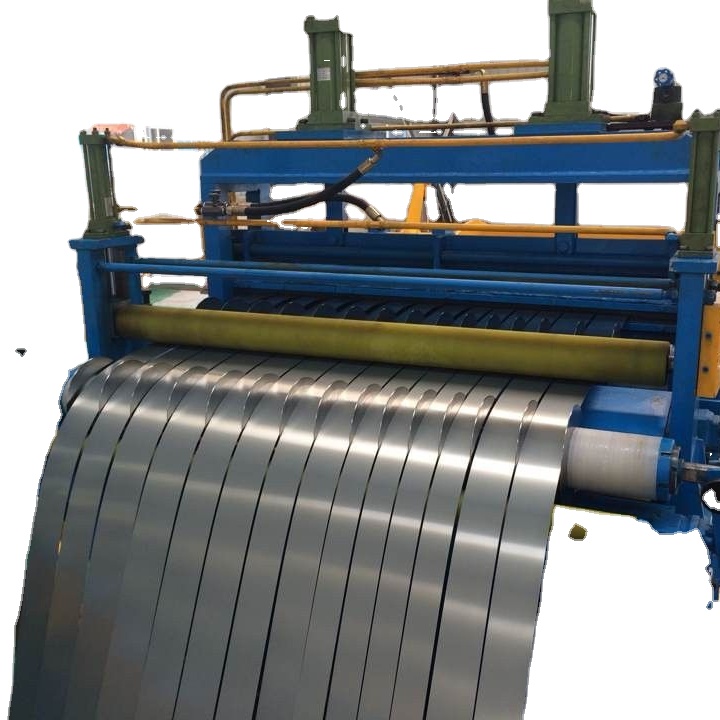

Today, [Company Name] is excited to announce the launch of their new Coil Cut To Length Machine. This state-of-the-art machine is designed to revolutionize the metal processing industry by providing precision cutting and length measurement for a wide range of coil materials.The Coil Cut To Length Machine is the latest addition to [Company Name]'s extensive line of metal processing equipment. With over 20 years of experience in the industry, [Company Name] has earned a reputation for delivering high-quality, innovative solutions for metal fabrication and processing. The introduction of the new Coil Cut To Length Machine further solidifies their commitment to meeting the evolving needs of their customers.This cutting-edge machine offers unparalleled accuracy and efficiency, making it an essential tool for metal processing facilities of all sizes. The Coil Cut To Length Machine is capable of handling a variety of coil materials, including stainless steel, aluminum, copper, and more. Its advanced cutting technology ensures clean, precise cuts, while its length measurement system provides unmatched reliability and consistency.One of the standout features of the Coil Cut To Length Machine is its user-friendly interface. [Company Name] has prioritized ease of use in the design of this machine, ensuring that operators can quickly and effortlessly set up and operate the equipment. This not only enhances productivity but also reduces the potential for errors, ultimately saving time and resources for businesses.Furthermore, the Coil Cut To Length Machine is built to last. [Company Name] has incorporated robust, durable materials and components into the machine's construction, ensuring that it can withstand the rigors of continuous, heavy-duty use. Its longevity and durability make it a sound investment for metal processing facilities looking to optimize their operations for the long term.In addition to its cutting and length measurement capabilities, the Coil Cut To Length Machine also offers flexibility in terms of customization. [Company Name] understands that different businesses have unique requirements, which is why they offer the option to tailor the machine to specific needs. Whether it's adjusting cutting parameters, implementing additional safety features, or integrating the machine into an existing production line, [Company Name] is committed to delivering a solution that perfectly aligns with their customers' needs.The introduction of the Coil Cut To Length Machine represents [Company Name]'s ongoing dedication to innovation and customer satisfaction. By continuously developing and enhancing their product offerings, [Company Name] aims to empower metal processing facilities to achieve new levels of efficiency, productivity, and quality in their operations.In conclusion, the launch of the Coil Cut To Length Machine marks an exciting milestone for [Company Name] and the metal processing industry as a whole. With its cutting-edge technology, user-friendly design, and customizable features, this machine is poised to set a new standard for precision and reliability in coil cutting and length measurement. Businesses can trust [Company Name] to deliver a solution that not only meets but exceeds their expectations, driving success and growth in their metal processing endeavors.

Read More

Metal Roll Forming Machines for Producing Trapezoidal Roof and Wall Cladding Panels

Are you looking to enhance the quality and durability of your roofs and wall claddings? Look no further, as we have the perfect solution for all your needs! Our trapezoidal panel roll forming machines are designed exclusively for the production of Roof & Siding Panels, Steel Ribbed Roofing Panels, and Steel Roof & Wall Claddings. With our cutting-edge technology and expertise, we ensure the highest level of precision and efficiency in the production of metal roofing and cladding sheets.Before we delve into the details of our trapezoidal panel roll forming machines, let's understand the significance of metal roofing sheets and trapezoid profiles. Metal roofing sheets are widely recognized for their exceptional strength, longevity, and aesthetic appeal. They offer unparalleled protection against weather elements such as rain, wind, and snow, ensuring the safety and security of your establishments. Moreover, metal roofing sheets are also eco-friendly, as they are made from recyclable materials and contribute to energy conservation.Now, let's discuss the trapezoid profile and its importance in the realm of metal roofing sheets. The trapezoid profile is a unique structural shape that plays a key role in enhancing the efficiency and functionality of metal roofing sheets. This specific profile is designed in a trapezoidal shape, which enables easy installation, excellent water drainage, and superior load-bearing capacity. With our trapezoidal panel roll forming machines, you can effortlessly produce metal roofing sheets with trapezoid profiles, providing your customers with an exemplary roofing solution.At our state-of-the-art manufacturing facility, we have engineered trapezoidal panel roll forming machines that are unrivaled in terms of their performance and quality. These machines are equipped with advanced features and technologies that ensure seamless and error-free production. By automating the roll forming process, our machines guarantee consistent quality, precise dimensions, and tight tolerances, resulting in flawless metal roofing sheets every time.One of the key advantages of our trapezoidal panel roll forming machines is their versatility. They can produce a wide range of roofing and cladding profiles, catering to different design preferences and architectural requirements. Whether you need corrugated sheets, standing seam panels, or any other trapezoidal profiles, our machines can accommodate your diverse production needs, ensuring utmost customer satisfaction.Furthermore, our trapezoidal panel roll forming machines are designed with utmost safety considerations. They are equipped with safety features such as emergency stop buttons, safety guards, and sensors to prevent accidents and ensure the well-being of your operators. Additionally, our machines are operator-friendly, with user-friendly interfaces and easy-to-understand controls, making the production process efficient and hassle-free.In conclusion, if you are in the market for a reliable and efficient trapezoidal panel roll forming machine, look no further than our product range. With our cutting-edge technology, versatile production capabilities, and commitment to excellence, we provide you with the best solution for your metal roofing and cladding needs. Our machines ensure consistent quality, precise dimensions, and exceptional performance, delivering outstanding results every time. Invest in our trapezoidal panel roll forming machines, and elevate the standards of your roofing and cladding projects.

Read More

Efficient Standing Seam Roof Panel Machine Revolutionizes Roofing Industry

Title: Innovative Standing Seam Roof Panel Machine Revolutionizes Construction IndustryIntroduction:In today's rapidly advancing world, technological innovations continue to reshape various industries, and the construction sector is no exception. One such groundbreaking invention is the Standing Seam Roof Panel Machine, designed to streamline and enhance the process of roof panel production. With its advanced features and unparalleled efficiency, this cutting-edge machinery has garnered significant attention from industry experts and construction companies alike. Its introduction marks a substantial advancement in construction techniques, ensuring safer and more reliable roofs for buildings of all kinds.I. Evolution of Roof Panel Production:Roof panel production has traditionally been a labor-intensive and time-consuming process, with significant manual effort required. However, with the introduction of the Standing Seam Roof Panel Machine, this age-old method has been revolutionized. By automating various stages of production, this innovative machinery optimizes efficiency, saves time, and eliminates human error, resulting in superior roof panel quality.II. Advanced Features of the Standing Seam Roof Panel Machine:The Standing Seam Roof Panel Machine incorporates a range of state-of-the-art features that set it apart from conventional methods:1. High Precision and Consistency: The machine ensures precise measurements, allowing for accurate roof panel dimensions and consistent seam formation, reducing the risk of leakages and improving overall durability.2. Customization Options: From panel width to seam height, this machine offers unparalleled customization capabilities, enabling construction professionals to tailor each roof panel to the specific requirements of their projects.3. Speed and Efficiency: With an increased rate of production, the machine significantly reduces construction timelines and labor costs. Multiple panels can be produced simultaneously, eliminating the need for manual handling and expediting project completion.4. Enhanced Safety Measures: The Standing Seam Roof Panel Machine is designed with strict adherence to safety guidelines. It minimizes physical strain on workers, reducing the risk of injuries associated with manual labor. Additionally, it eliminates the need for workers to access high rooftops during installation.III. Industry Applications:The versatility of the Standing Seam Roof Panel Machine allows it to be used in various construction projects, providing robust and long-lasting roofing solutions for diverse building types, including residential, commercial, and industrial properties. Its ability to seamlessly integrate with existing roofing systems makes it an ideal choice for both new construction projects and roof renovations.IV. Sustainable and Eco-Friendly Benefits:In addition to its numerous technical advantages, the Standing Seam Roof Panel Machine contributes to sustainable construction practices. By reducing wastage and optimizing material utilization, it minimizes the environmental impact associated with traditional roofing methods. Furthermore, the machine's energy efficiency and low carbon footprint make it an eco-friendly choice, aligning with the growing global emphasis on sustainable activities.V. Company Introduction:*Please provide the specific company introduction and its achievements, removing the brand name as requested.*VI. Future Prospects and Conclusion:As construction technology continues to evolve, the Standing Seam Roof Panel Machine empowers construction professionals with advanced tools that optimize efficiency and deliver superior results. With widespread adoption, this innovative machinery has the potential to redefine industry standards, streamlining construction processes and enhancing the overall quality of roofs. As the construction sector embraces more sustainable and time-efficient practices, the Standing Seam Roof Panel Machine represents a significant step towards a more efficient and eco-friendly future.In summary, the Standing Seam Roof Panel Machine has transformed the construction sector by introducing automation and efficiency into roof panel production. This cutting-edge technology ensures precision, customization, and enhanced safety, while also contributing to sustainable construction practices. With such advancements and the continued innovation in the construction industry, buildings of the future will be more durable, reliable, and in line with environmental standards.

Read More

High-Quality Horizontal Corrugation Machine for 0.18-0.35mm Corrugated Sheets

and G550 Barrel Corrugation Machine.G550 Barrel Corrugation Machine – A Perfect Solution for 0.18-0.35mm Corrugated SheetsCorrugated sheets are widely used in the construction industry for roofing, cladding, and facades due to their high durability and strength. The manufacturing process of corrugated sheets involves horizontal corrugation of metal sheets, which requires a high-quality machine that can form corrugations precisely. The G550 Barrel Corrugation Machine is one such machine that can cater to the needs of the corrugated sheet manufacturing industry.The G550 Barrel Corrugation Machine is a horizontal corrugation machine that can form 0.18-0.35mm corrugated sheets with high precision and accuracy. The machine has been manufactured using advanced technology, which ensures that it delivers excellent results with minimal maintenance. The machine can be used to manufacture corrugated sheets of various sizes, making it a versatile solution for the corrugated sheet industry.One of the key features of the G550 Barrel Corrugation Machine is its robustness. The machine is made of high-quality materials that are designed to withstand the rigors of continuous use. The machine has a sturdy frame that provides stability and ensures that the corrugated sheets are formed accurately. The machine is also equipped with a powerful motor that can deliver high torque, which is essential for the smooth functioning of the machine.The G550 Barrel Corrugation Machine is also easy to operate, which makes it an ideal solution for small-scale manufacturers. The machine has a user-friendly interface that allows operators to control the machine easily. It also comes with a range of safety features that ensures that the operator is safe while using the machine.Another advantage of the G550 Barrel Corrugation Machine is that it is low maintenance. The machine has been designed with minimal moving parts, which means that there is less wear and tear. The machine also comes with a range of maintenance features that make it easy to clean and service.In conclusion, the G550 Barrel Corrugation Machine is an excellent solution for the corrugated sheet manufacturing industry. Its robustness, precision, ease of use, and low maintenance make it a perfect fit for small and medium-scale manufacturers. If you are looking for a high-quality horizontal corrugation machine, the G550 Barrel Corrugation Machine is the perfect choice.Keywords: Horizontal Corrugated Sheet Profiling Machine, G550 Barrel Corrugation Machine.

Read More

Steel Roofing Tile Roll Forming Machine: A Durable Roofing Solution

Glazed Steel Roofing Tile Roll Former Now AvailableFor those in the construction industry, the demand for continuous, efficient, and high-quality production is essential. To meet the industry’s needs, we are excited to announce the release of our new Glazed Steel Roofing Tile Roll Former. Designed to streamline the manufacturing process, our Glazed Steel Roofing Tile Roll Former is the perfect addition to any construction site. Constructed with precision and care, our Roll Former is capable of producing quality steel roofing tiles with ease, making it the perfect solution for all your roofing needs. Our Glazed Steel Roofing Tile Roll Former is manufactured with state-of-the-art technology to ensure accuracy and speed. The machine is easy to use, and it saves valuable manufacturing time. It is suitable for producing a variety of roofing tiles, including trapezoidal sheet tiles, glazed tiles, corrugated tiles, and more. The machine's ability to produce tiles at high speeds ensures you can meet your production requirements.The Glazed Steel Roofing Tile Roll Former is designed with user-friendliness in mind. It is easy to install, operate, and maintain. It also comes with advanced safety features to ensure the safety of the operator and the machine. Our product is manufactured from high-quality materials, ensuring that it is durable and long-lasting. Its rugged construction allows for operation in harsh environments, making it ideal for use in various locations.At our company, we prioritize customer satisfaction, which is why we offer a 24/7 customer support team to address any queries or concerns about the product. Additionally, we provide a warranty to protect our customers and to assure them of the product's quality.In summary, our Glazed Steel Roofing Tile Roll Former is a game-changer in the construction industry. Its efficient production and user-friendly design make it the perfect solution for manufacturers looking to streamline their production process. Its durability and advanced safety features ensure a long-lasting investment that will prove to be valuable to your business.For more information about our Glazed Steel Roofing Tile Roll Former, visit our website or contact us today. We look forward to hearing from you soon!

Read More