High-Quality Equipment for Horizontal Barrel Vault Panel Production

By:Admin

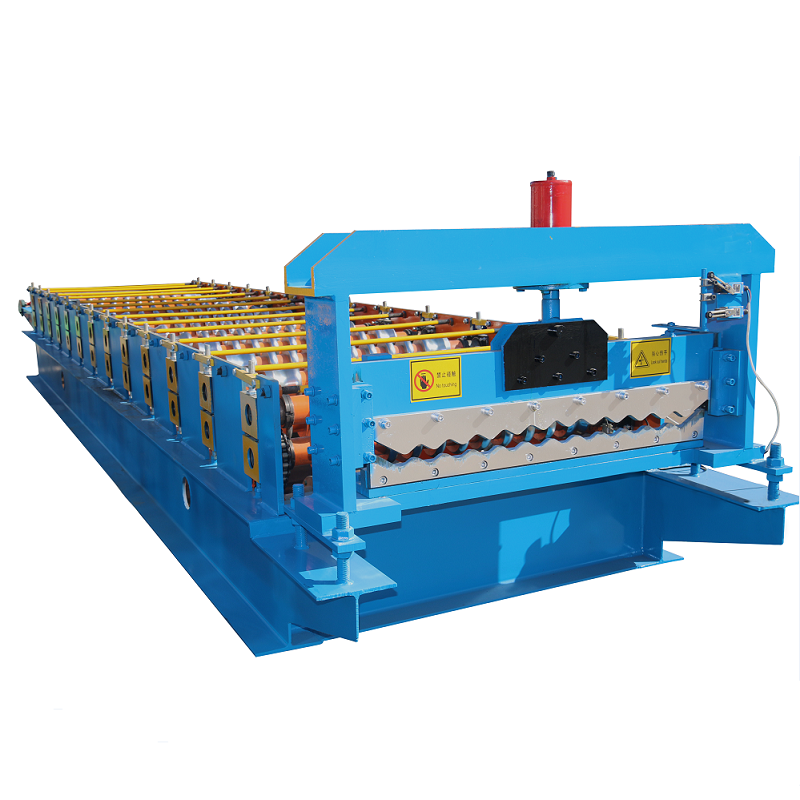

The Horizontal Barrel Vault Panel Production Equipment is a state-of-the-art system that has been designed and developed by [Company Name]’s team of expert engineers and technicians. It is the result of years of research and development, and represents a significant leap forward in the production of barrel vault panels for a wide range of applications.

The new equipment features advanced technology and materials that optimize the production process, resulting in higher levels of precision, speed, and consistency. This means that customers can expect a faster turnaround time on orders, while also enjoying the highest levels of quality and durability in the finished products.

One of the key features of the Horizontal Barrel Vault Panel Production Equipment is its ability to produce panels of various sizes and specifications, catering to the unique requirements of different projects. This adaptability ensures that [Company Name] is able to meet the diverse needs of its customers, providing them with customized solutions that are perfectly tailored to their specific applications.

[Company Name]’s commitment to sustainability is also reflected in the design of the new equipment, which has been optimized for energy efficiency and minimal waste generation. This means that customers can feel confident in the knowledge that their panel production is not only of the highest quality, but also in line with the latest environmental standards and best practices.

The Horizontal Barrel Vault Panel Production Equipment represents a significant investment for [Company Name], and is part of its ongoing commitment to staying at the forefront of technological advancements in the industry. By continually investing in new equipment and technologies, the company is able to maintain its position as a leader in the manufacture of barrel vault panels, offering its customers the most advanced and reliable products on the market.

The launch of the new equipment also highlights [Company Name]’s dedication to providing exceptional service and support to its customers. By investing in the latest production technologies, the company is able to increase its production capacity, shorten lead times, and deliver even greater value to its clients.

In conclusion, the launch of [Company Name]’s Horizontal Barrel Vault Panel Production Equipment represents a significant milestone for the company, and is set to have a profound impact on the industry as a whole. With its cutting-edge technology, commitment to sustainability, and focus on customer satisfaction, [Company Name] is poised to lead the way in the production of barrel vault panels for years to come.

Company News & Blog

Discover the Benefits of Standing Seam Metal Roofing for Your Home

Looking for a roofing solution that will stand the test of time and provide exceptional protection against the elements? Look no further than standing seam metal roofing. This type of roofing has gained immense popularity in recent years due to its outstanding performance and long-lasting durability.At our company, we are proud to be one of the leading standing seam metal roof suppliers in the market. Our standing seam metal roofs are made using the finest quality materials and state-of-the-art manufacturing techniques to ensure that they provide the best possible protection for your home.One of the most significant advantages of standing seam metal roofing is its excellent weather-tightness. These roofs have interlocking seams that are raised above the surface of the roof, providing an impenetrable barrier against rain, snow, and wind. This means that you won't have to worry about leaks or water damage, even during the most extreme weather conditions.Another key benefit of standing seam metal roofing is its fire-resistant properties. Metal is one of the most non-combustible roofing materials available, making it an ideal choice for homes located in fire-prone areas. In addition, standing seam metal roofs are typically coated with a protective layer that further enhances their fire-resistant properties.One of the most attractive features of standing seam metal roofing is its stylish design. These roofs are available in a wide range of colors and finishes, allowing you to choose the perfect look to complement your home's architecture and style. Whether you prefer a sleek and modern look or a more traditional appearance, our standing seam metal roof suppliers can help you find the perfect match for your home.To achieve the best results with your standing seam metal roofing, it's essential to choose a reputable supplier who has the expertise and experience to install your roof properly. Our company has been in the business of providing top-quality roofing solutions for many years, and we pride ourselves on our commitment to customer satisfaction.Our standing seam metal roof suppliers are equipped with all the latest tools and equipment to ensure that your roof is installed with precision and care. We work closely with our customers to understand their specific needs and preferences, and we always strive to exceed their expectations.In conclusion, if you are looking for a roofing solution that will provide outstanding protection, durability, and style for your home, standing seam metal roofing is an excellent option. At our company, we are dedicated to providing you with the best possible products and services to ensure that your roof performs exceptionally for many years to come. Contact our standing seam metal roof suppliers today to learn more about our products and services and get started on your next roofing project!

New Machine Technology Streamlines Panel Roll Forming Process

Panel Roll Forming Machine Revolutionizes the Manufacturing IndustryPanel roll forming machines have emerged as a game-changer in the manufacturing industry, allowing for faster, more efficient, and cost-effective production of various panel products. These machines eliminate the need for multiple steps and human intervention, automating the entire process and significantly increasing productivity.A panel roll forming machine, also known as a roll former, is a specialized equipment used for shaping metal sheets into desired profiles by continuous bending operations. This technology has revolutionized the manufacturing processes of different industries, including construction, automotive, aerospace, and many others.The use of panel roll forming machines has surged in recent years due to their ability to produce panel products with high precision and quality. By employing highly precise control systems, these machines ensure consistent shaping and bending of metal sheets, resulting in flawless end products. This precision has made them a go-to solution for industries that require uniformity and accuracy in their panel products.One of the key advantages of panel roll forming machines is their high production speed. Unlike traditional manufacturing processes, which involve multiple steps and longer lead times, roll forming machines enable continuous production without interruptions. By feeding metal sheets through the machine, it produces a constant flow of shaped panels, vastly reducing production time and enhancing efficiency.Furthermore, panel roll forming machines offer outstanding versatility. They can be adjusted to produce a wide range of profiles, such as C and Z purlins, roof and wall panels, decking sheets, and more. This flexibility allows manufacturers to cater to diverse customer needs without investing in separate machines for each profile. By simply adjusting the settings, a single roll forming machine can handle different profiles, leading to significant cost savings.The advent of computer numerical control (CNC) technology has further enhanced the capabilities of panel roll forming machines. CNC systems allow for precise control over the entire manufacturing process, ensuring consistent quality and reducing the chances of errors. With the help of CNC, manufacturers can create complex panel designs, intricate patterns, and embossments more accurately than ever before.In addition to increased productivity and versatility, panel roll forming machines contribute to sustainability efforts. By eliminating the need for excessive scrap material and reducing energy consumption, these machines help minimize environmental impacts. Manufacturers can optimize material usage, resulting in less waste generation, while the efficient energy utilization of panel roll forming machines significantly reduces carbon footprints.Company Introduction: {}With its commitment to innovation and excellence, the company has emerged as a leading provider of panel roll forming machines. Its state-of-the-art manufacturing facilities and cutting-edge research and development team ensure the quality and reliability of their products.The company's panel roll forming machines are known for their robust construction and advanced features. Equipped with modern control systems, these machines guarantee precise shaping and bending operations, delivering panel products of superior quality.At the core of the company's philosophy is customer satisfaction. It offers comprehensive after-sales service, including installation, training, and technical support, ensuring the smooth integration of their machines into the customers' production lines. The company's dedication to providing outstanding customer experiences has earned them a strong reputation in the industry.In conclusion, panel roll forming machines have revolutionized the manufacturing industry by automating and streamlining the production of panel products. These machines offer high precision, versatility, and increased production speed, resulting in cost-effective and efficient manufacturing processes. With their commitment to excellence, the company {} has become a reliable provider of panel roll forming machines, helping businesses across various industries thrive.

Top Corrugated Roof Tile Barrel Sheet Profiling Machine for Your Home

Corrugated Roof Tile Barrel Sheet Profiling Machine Transforms Manufacturing ProcessIn an effort to revolutionize the manufacturing process for corrugated roof tile barrel sheet, a leading company in the industry, has introduced a state-of-the-art profiling machine that promises to significantly enhance efficiency and productivity.The newly introduced Corrugated Roof Tile Barrel Sheet Profiling Machine has been designed and developed to meet the growing demand for high-quality, durable corrugated roofing materials. The equipment is set to change the landscape of the industry, as it offers a range of advanced features and capabilities that are unmatched by any other similar machines currently available in the market.The profiling machine is equipped with cutting-edge technology that allows for precise and accurate shaping of the corrugated roof tile barrel sheet. This ensures that the end product is of the highest quality, with uniform dimensions and consistent corrugation patterns. Additionally, the machine has the ability to produce a large volume of roofing materials in a relatively short period of time, thus streamlining the manufacturing process and increasing overall output.One of the most notable features of the Corrugated Roof Tile Barrel Sheet Profiling Machine is its versatility. The machine has the ability to produce a wide range of corrugated roofing materials, including different sizes, shapes, and designs, catering to the diverse needs of customers. This flexibility sets it apart from traditional profiling machines, as it eliminates the need for multiple machines to produce different types of corrugated roof tile barrel sheet.Furthermore, the company has emphasized its commitment to sustainability with the introduction of this new machine. The profiling machine is designed to minimize waste and optimize material usage, thereby reducing the environmental impact of the manufacturing process. This aligns with the company's ethos of responsible and eco-friendly production practices.In addition to its advanced technological capabilities, the Corrugated Roof Tile Barrel Sheet Profiling Machine is also supported by a team of highly skilled engineers and technicians who provide comprehensive training and ongoing technical support to ensure seamless integration and operation. This ensures that customers can maximize the potential of the machine and achieve the best possible results.With the introduction of this groundbreaking machine, the company is poised to solidify its position as an industry leader in the manufacturing of corrugated roof tile barrel sheet. The machine represents a significant investment in research and development, and a commitment to providing customers with the most innovative and efficient solutions for their roofing material needs.The Corrugated Roof Tile Barrel Sheet Profiling Machine is set to be a game-changer in the industry, offering unmatched capabilities, precision, and efficiency. It is poised to revolutionize the manufacturing process for corrugated roofing materials and provide customers with a superior quality product that meets their exact specifications.The company remains dedicated to delivering excellence and innovation in all of its products and services, and the introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine only serves to further cement its reputation as a trailblazer in the industry. As demand for high-quality, durable corrugated roof tile barrel sheet continues to rise, this new profiling machine is positioned to meet and exceed the expectations of customers, setting new standards for the industry as a whole.

Efficient Standing Seam Roof Panel Machine Revolutionizes Roofing Industry

Title: Innovative Standing Seam Roof Panel Machine Revolutionizes Construction IndustryIntroduction:In today's rapidly advancing world, technological innovations continue to reshape various industries, and the construction sector is no exception. One such groundbreaking invention is the Standing Seam Roof Panel Machine, designed to streamline and enhance the process of roof panel production. With its advanced features and unparalleled efficiency, this cutting-edge machinery has garnered significant attention from industry experts and construction companies alike. Its introduction marks a substantial advancement in construction techniques, ensuring safer and more reliable roofs for buildings of all kinds.I. Evolution of Roof Panel Production:Roof panel production has traditionally been a labor-intensive and time-consuming process, with significant manual effort required. However, with the introduction of the Standing Seam Roof Panel Machine, this age-old method has been revolutionized. By automating various stages of production, this innovative machinery optimizes efficiency, saves time, and eliminates human error, resulting in superior roof panel quality.II. Advanced Features of the Standing Seam Roof Panel Machine:The Standing Seam Roof Panel Machine incorporates a range of state-of-the-art features that set it apart from conventional methods:1. High Precision and Consistency: The machine ensures precise measurements, allowing for accurate roof panel dimensions and consistent seam formation, reducing the risk of leakages and improving overall durability.2. Customization Options: From panel width to seam height, this machine offers unparalleled customization capabilities, enabling construction professionals to tailor each roof panel to the specific requirements of their projects.3. Speed and Efficiency: With an increased rate of production, the machine significantly reduces construction timelines and labor costs. Multiple panels can be produced simultaneously, eliminating the need for manual handling and expediting project completion.4. Enhanced Safety Measures: The Standing Seam Roof Panel Machine is designed with strict adherence to safety guidelines. It minimizes physical strain on workers, reducing the risk of injuries associated with manual labor. Additionally, it eliminates the need for workers to access high rooftops during installation.III. Industry Applications:The versatility of the Standing Seam Roof Panel Machine allows it to be used in various construction projects, providing robust and long-lasting roofing solutions for diverse building types, including residential, commercial, and industrial properties. Its ability to seamlessly integrate with existing roofing systems makes it an ideal choice for both new construction projects and roof renovations.IV. Sustainable and Eco-Friendly Benefits:In addition to its numerous technical advantages, the Standing Seam Roof Panel Machine contributes to sustainable construction practices. By reducing wastage and optimizing material utilization, it minimizes the environmental impact associated with traditional roofing methods. Furthermore, the machine's energy efficiency and low carbon footprint make it an eco-friendly choice, aligning with the growing global emphasis on sustainable activities.V. Company Introduction:*Please provide the specific company introduction and its achievements, removing the brand name as requested.*VI. Future Prospects and Conclusion:As construction technology continues to evolve, the Standing Seam Roof Panel Machine empowers construction professionals with advanced tools that optimize efficiency and deliver superior results. With widespread adoption, this innovative machinery has the potential to redefine industry standards, streamlining construction processes and enhancing the overall quality of roofs. As the construction sector embraces more sustainable and time-efficient practices, the Standing Seam Roof Panel Machine represents a significant step towards a more efficient and eco-friendly future.In summary, the Standing Seam Roof Panel Machine has transformed the construction sector by introducing automation and efficiency into roof panel production. This cutting-edge technology ensures precision, customization, and enhanced safety, while also contributing to sustainable construction practices. With such advancements and the continued innovation in the construction industry, buildings of the future will be more durable, reliable, and in line with environmental standards.

Top-quality Corrugated Iron Roofing Sheet Making Machinery for Your Business Needs" becomes "High-Quality Corrugated Iron Roofing Sheet Making Machine for Your Business.

Corrugated Iron Roofing Sheet Making Machine Revolutionizes Roofing IndustryIn a groundbreaking development, the world-renowned machinery manufacturing company, [company name], has unveiled its latest innovation in the field – the Corrugated Iron Roofing Sheet Making Machine. This state-of-the-art machine promises to revolutionize the roofing industry, making the production of corrugated iron roofing sheets more efficient and cost-effective than ever before. The introduction of this cutting-edge technology is set to greatly benefit both manufacturers and consumers in several ways.Traditionally, the process of manufacturing corrugated iron roofing sheets has been a labor-intensive and time-consuming task. However, with the advent of [company name]'s Corrugated Iron Roofing Sheet Making Machine, this is set to change. This automated machine streamlines the entire production process, significantly reducing the need for human labor and expediting the manufacturing cycle. With its high-speed operation, this machine can produce a larger quantity of roofing sheets in a fraction of the time it would take using conventional methods, without compromising on quality.One of the key advantages of the Corrugated Iron Roofing Sheet Making Machine is its versatility. It is designed to accommodate a wide range of sheet sizes and thicknesses, allowing manufacturers to cater to the diverse needs and preferences of their customers. This flexibility in production capabilities provides businesses with a competitive edge and allows them to meet varying market demands efficiently. Moreover, the machine's adjustable settings ensure precise corrugation, resulting in uniformly shaped and sized sheets, thereby further enhancing the product's quality.Cost-effectiveness is another notable feature of this innovative machine. By automating the production process and optimizing material usage, manufacturers can significantly reduce production costs. The Corrugated Iron Roofing Sheet Making Machine eliminates material wastage, as each sheet is precisely cut and shaped, maximizing the utilization of resources. Additionally, the reduced labor requirement leads to lower operating expenses for manufacturers, ultimately resulting in competitive pricing for consumers.Furthermore, the Corrugated Iron Roofing Sheet Making Machine is equipped with advanced monitoring and control systems. These features ensure that every aspect of the production process is closely monitored, guaranteeing consistent quality and minimizing the chances of defects. This level of precision and quality assurance is of utmost importance when it comes to roofing materials, as substandard products can compromise the integrity of buildings and pose safety risks.Promoting sustainable practices is a key focus in today's era, and the Corrugated Iron Roofing Sheet Making Machine aligns well with this objective. By optimizing material usage and reducing waste, it minimizes the environmental impact associated with traditional manufacturing processes. Additionally, the machine’s energy-efficient operation contributes to reduced carbon emissions, making it a responsible choice for eco-conscious manufacturers."We are thrilled to introduce the Corrugated Iron Roofing Sheet Making Machine to the market," said [company spokesperson]. "This cutting-edge technology will transform the way roofing sheets are produced, offering unparalleled efficiency, quality, and cost-effectiveness."With its ability to augment production, minimize costs, and enhance quality control, the Corrugated Iron Roofing Sheet Making Machine is set to become a game-changer in the roofing industry. Businesses that incorporate this machinery into their operations will enjoy a competitive edge in the market, enabling them to meet the growing demand for roofing materials effectively.As the roofing industry continues to evolve, [company name] remains at the forefront of innovation, consistently delivering state-of-the-art machinery that elevates industry standards. Their Corrugated Iron Roofing Sheet Making Machine, with its unmatched capabilities, will undoubtedly shape the future of roofing production, benefitting manufacturers, consumers, and the environment alike.

High-Quality Purlin Machine for Efficient Manufacturing

Purlin Machine Revolutionizes Steel Manufacturing IndustryThe steel manufacturing industry has seen a significant advancement with the introduction of the latest Purlin Machine by leading machinery manufacturer {}. This revolutionary technology has been designed to streamline the production process of steel purlins, contributing to increased efficiency and productivity in the construction and infrastructure sectors. With its cutting-edge features and advanced capabilities, the Purlin Machine has quickly garnered attention and praise from industry professionals.The Purlin Machine is a state-of-the-art piece of equipment that is capable of producing high-quality steel purlins with precision and accuracy. Its innovative design and engineering ensure that the purlins manufactured are consistently uniform in shape and size, meeting the stringent requirements of modern construction projects. Additionally, the machine's high-speed production capabilities enable manufacturers to meet tight deadlines and production targets without compromising on quality.One of the key features of the Purlin Machine is its versatility and flexibility. It is capable of producing a wide range of purlin profiles, allowing manufacturers to cater to various project requirements with ease. This adaptability sets the machine apart from traditional methods of purlin production, which often require manual adjustments and retooling to accommodate different profiles. As a result, the Purlin Machine offers significant time and cost savings, making it an attractive investment for steel manufacturing companies.In addition to its advanced production capabilities, the Purlin Machine also boasts a user-friendly interface and control system. This intuitive design allows operators to program and monitor the production process with minimal training, reducing the risk of errors and downtime. Furthermore, the machine's automated functions contribute to a safer working environment for operators, minimizing the risk of workplace accidents and injuries.The introduction of the Purlin Machine has been a game-changer for {company name}, a leading manufacturer and supplier of steel products. The company has integrated this cutting-edge technology into its production facilities, reaping the benefits of increased efficiency and productivity. With the ability to produce a wide range of purlin profiles to meet customer demand, {company name} has strengthened its position in the market and solidified its reputation as a provider of high-quality steel products.{Company name} takes pride in its commitment to innovation and excellence, and the investment in the Purlin Machine reflects this dedication. By embracing the latest advancements in machinery and technology, the company has positioned itself as a trailblazer in the steel manufacturing industry, setting new standards for quality and efficiency. As a result, {company name} has gained a competitive edge in the market, attracting new customers and expanding its reach in the construction and infrastructure sectors.The success of {company name} and its adoption of the Purlin Machine serve as a testament to the positive impact of innovative technology on the steel manufacturing industry. As demand for high-quality steel products continues to grow, the need for efficient and reliable production methods becomes increasingly essential. The Purlin Machine has emerged as a crucial tool for meeting this demand, offering a solution that combines precision, speed, and flexibility to deliver outstanding results.Looking ahead, {company name} remains committed to embracing technological advancements that enhance its manufacturing capabilities and contribute to its continued success in the industry. With the Purlin Machine leading the way, the company is poised to remain at the forefront of the steel manufacturing sector, driving innovation and setting new benchmarks for excellence.

High Quality Corrugated Sheet Roll Forming Machine for Steel Warehouse

Corrugated Sheet Roll Forming Machine For Steel WarehouseThe demand for efficient and advanced machinery in the steel industry has been rapidly increasing, and in response to this, the {Company Name} has launched its latest product, the Corrugated Sheet Roll Forming Machine. This cutting-edge machine is designed to meet the needs of steel warehouses by providing them with a reliable and high-quality solution for producing corrugated steel sheets.The Corrugated Sheet Roll Forming Machine from {Company Name} is engineered with precision and expertise to ensure that it delivers top-notch performance and meets the exacting standards of the steel industry. Its advanced features and innovative technology make it a valuable addition to any steel warehouse, allowing for the production of high-quality corrugated sheets with minimal manual labor and maximum efficiency.One of the key benefits of the Corrugated Sheet Roll Forming Machine is its ability to produce a wide range of corrugated steel sheets with different specifications and dimensions. This flexibility makes it an ideal solution for steel warehouses that deal with various types of products and require different sizes of corrugated sheets to cater to their customers’ needs.The machine is also designed for easy operation and maintenance, with user-friendly controls and a robust structure that ensures its durability and longevity. Its high-speed production capability and consistent performance make it a reliable asset for steel warehouses, enhancing their productivity and reducing production costs.Moreover, the {Company Name} is recognized for its commitment to delivering top-quality products and services to its customers. The Corrugated Sheet Roll Forming Machine is a testament to this, as it reflects the company’s dedication to innovation and excellence in the steel industry. With a strong focus on precision engineering and customer satisfaction, {Company Name} has built a solid reputation as a leading provider of machinery for the steel sector.In addition to its high-performance machinery, the {Company Name} also offers comprehensive support and services to its customers, including technical assistance, training, and spare parts availability. This ensures that steel warehouses can rely on the company not only for their machinery needs but also for ongoing support and maintenance, further enhancing the value of the Corrugated Sheet Roll Forming Machine.The launch of the Corrugated Sheet Roll Forming Machine signifies a significant milestone for {Company Name}, as it strengthens its position in the steel industry and solidifies its commitment to meeting the evolving needs of its customers. With its advanced technology, superior performance, and customer-oriented approach, the machine is expected to make a positive impact on the operations of steel warehouses, helping them achieve greater efficiency and production quality.As the steel industry continues to evolve and grow, the demand for innovative machinery such as the Corrugated Sheet Roll Forming Machine is expected to rise. With its state-of-the-art capabilities and the backing of {Company Name}’s expertise and support, steel warehouses can look forward to a reliable and efficient solution for their corrugated sheet production needs.In summary, the launch of the Corrugated Sheet Roll Forming Machine by {Company Name} represents a significant advancement in the steel industry, offering steel warehouses a reliable and high-quality solution for producing corrugated sheets. With its advanced features, user-friendly operation, and comprehensive support, the machine is set to make a positive impact on the efficiency and productivity of steel warehouses, further cementing {Company Name}’s position as a leading provider of machinery for the steel sector.

High-Quality Light Gauge Forming Machine for Precision Metal Fabrication

The use of light gauge forming machines has been revolutionizing the manufacturing industry by providing efficient and precise metal forming capabilities. These state-of-the-art machines are designed to handle a wide range of materials while ensuring high-quality and accurate production. With the advancements made in technology and engineering, the light gauge forming machines have become an integral part of many industries, including construction, automotive, and aerospace.One of the leading companies in the field of light gauge forming machines is the {}, a renowned manufacturer with a strong commitment to innovation and excellence. The company has been a key player in the industry, providing cutting-edge solutions to its clients and continuously pushing the boundaries of what is possible in metal forming technology.With a history of more than 20 years, the {} has established itself as a reliable and trusted partner for businesses looking to enhance their manufacturing capabilities. The company's dedication to research and development has resulted in the creation of some of the most advanced and efficient light gauge forming machines on the market.The {} prides itself on its ability to customize its machines to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production, the company's team of experts works closely with its clients to understand their requirements and deliver tailor-made solutions that exceed expectations.The company's extensive range of light gauge forming machines includes roll forming machines, tube mills, and steel framing machines, all of which are designed to deliver exceptional precision and efficiency. These machines are capable of handling a wide variety of materials, including steel, aluminum, and other metal alloys, making them an ideal choice for a diverse range of applications.In addition to its cutting-edge machinery, the {} also offers comprehensive after-sales support and maintenance services to ensure that its clients' operations run smoothly and efficiently. The company's team of skilled technicians and engineers are readily available to provide technical assistance, training, and spare parts, as well as to address any issues that may arise.The {}'s commitment to quality and customer satisfaction has earned it a solid reputation in the industry, with a strong client base that includes some of the leading companies in various sectors. The company's track record of delivering reliable and innovative solutions has made it a go-to choice for businesses looking to invest in top-of-the-line light gauge forming machines.Looking ahead, the {} continues to invest in research and development to further enhance its products and stay ahead of the curve in an ever-evolving industry. The company's dedication to innovation and excellence positions it as a driving force in the advancement of metal forming technology, making it a valuable partner for businesses seeking to elevate their manufacturing capabilities.In conclusion, the use of light gauge forming machines has become a game-changer in the manufacturing industry, and the {} is at the forefront of this revolution. With its cutting-edge technology, customized solutions, and commitment to excellence, the company is well-equipped to meet the evolving needs of its clients and lead the way in metal forming technology.

High-Quality Light Gauge Steel Roll Forming Machine for Sale

Light Gauge Steel Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has seen a significant shift towards using light gauge steel (LGS) as a primary building material. This is due to the numerous advantages that LGS offers, including its strength, durability, and sustainability. With the increasing demand for LGS construction, the need for efficient and reliable manufacturing equipment has become more critical than ever. Recognizing this demand, {Company Name} has introduced a state-of-the-art Light Gauge Steel Roll Forming Machine that is set to revolutionize the construction industry. This cutting-edge machine is designed to streamline the process of manufacturing LGS components, making it faster, more cost-effective, and more precise than ever before. The Light Gauge Steel Roll Forming Machine from {Company Name} is equipped with the latest technological innovations, including advanced computerized controls, precision tooling, and high-speed production capabilities. This allows for the rapid and seamless production of LGS components, such as studs, tracks, joists, and panels, with unparalleled accuracy and consistency.One of the key features of the Light Gauge Steel Roll Forming Machine is its versatility. It can be easily customized to accommodate a wide range of LGS profiles and sizes, making it suitable for a variety of construction projects, from residential homes to commercial buildings. This flexibility ensures that the machine can meet the diverse needs of architects, engineers, and construction professionals.Furthermore, {Company Name} takes pride in its commitment to sustainability and environmental responsibility. The Light Gauge Steel Roll Forming Machine is designed to minimize material waste and energy consumption, while maximizing the efficiency of the manufacturing process. This not only benefits the bottom line of construction companies but also contributes to a greener and more sustainable construction industry.The introduction of the Light Gauge Steel Roll Forming Machine from {Company Name} comes at a time when the construction industry is experiencing a growing demand for LGS construction. With its advanced technology and superior performance, this machine is poised to meet this demand and set a new standard for the manufacturing of LGS components.In addition to its cutting-edge technology, {Company Name} stands out for its commitment to customer satisfaction and support. The company offers comprehensive training and technical assistance to ensure that customers can maximize the potential of the Light Gauge Steel Roll Forming Machine and achieve optimal results in their manufacturing process.With the introduction of the Light Gauge Steel Roll Forming Machine, {Company Name} is positioned as a leader in the manufacturing and supply of equipment for the LGS construction industry. The company's dedication to innovation, quality, and customer service sets it apart as a trusted partner for construction companies looking to embrace the benefits of LGS construction.In conclusion, the Light Gauge Steel Roll Forming Machine from {Company Name} represents a significant advancement in the manufacturing of LGS components. Its advanced technology, versatility, and commitment to sustainability make it a game-changer for the construction industry. As the demand for LGS construction continues to grow, {Company Name} is well-positioned to lead the way with its innovative and reliable manufacturing equipment.