Top Quality Corrugated Iron Making Machine for Sale - Find Out More!

By:Admin

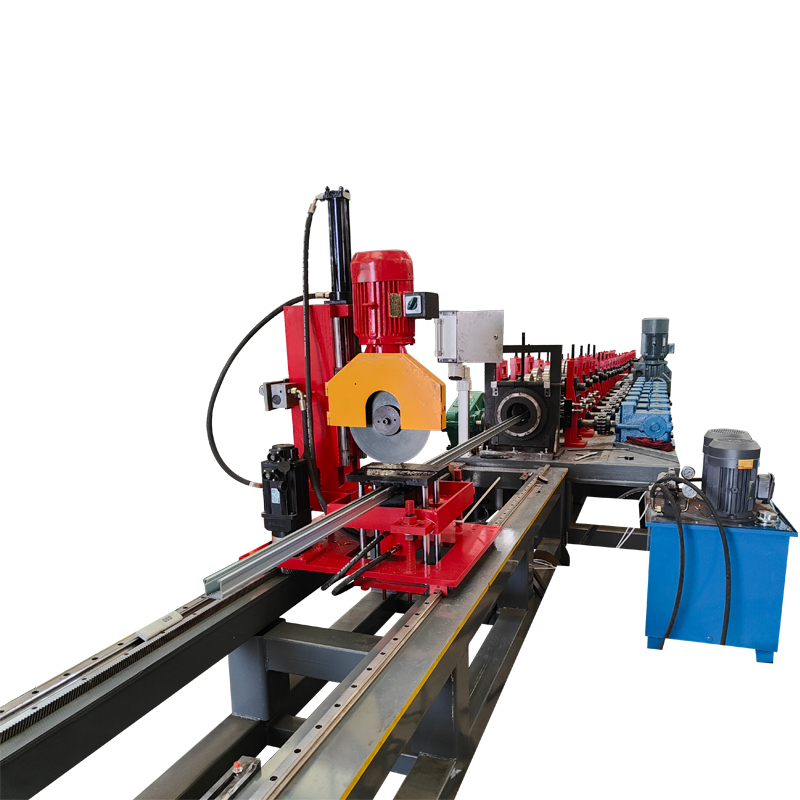

The new corrugated iron making machine is designed to streamline the production process, offering increased efficiency and precision. Featuring advanced technology and automated systems, this state-of-the-art machine is capable of producing corrugated iron sheets with unparalleled accuracy and consistency. The innovative design of the machine allows for flexibility in the production of various gauges and sizes, ensuring that it meets the diverse needs of the construction industry.

One of the key highlights of the new corrugated iron making machine is its ability to decrease material waste and optimize resource utilization. By utilizing cutting-edge manufacturing techniques, the machine minimizes scrap material and maximizes the yield of high-quality corrugated iron sheets. This not only contributes to cost savings for manufacturers but also aligns with the growing emphasis on sustainable manufacturing practices.

In addition to its cutting-edge technology, the new corrugated iron making machine is also equipped with advanced safety features to ensure a secure working environment for operators. With the incorporation of automated controls and safety protocols, the machine prioritizes the well-being of workers while maintaining high productivity levels.

Furthermore, the company's dedication to providing comprehensive training and technical support sets it apart from its competitors. With a team of experienced engineers and technicians, the company offers on-site training for operators and maintenance personnel, ensuring that they are proficient in operating and maintaining the new machine. This commitment to customer satisfaction underscores the company's reputation as a trusted partner in the metalworking industry.

The introduction of the new corrugated iron making machine is poised to have a significant impact on the manufacturing sector, particularly in the construction and building materials industry. Its cutting-edge technology, combined with the company's expertise and commitment to excellence, positions it as a game-changer in the production of corrugated iron.

As the demand for durable and versatile building materials continues to rise, the new machine is well-positioned to cater to the evolving needs of the market. Its ability to deliver high-quality corrugated iron sheets with unmatched precision and efficiency will undoubtedly set new standards in the industry.

In conclusion, the unveiling of the new corrugated iron making machine represents a significant milestone for the company and the manufacturing sector as a whole. With its sophisticated technology, focus on sustainability, and dedication to customer satisfaction, the machine is set to redefine the production of corrugated iron and elevate the industry to new heights. As the company continues to push the boundaries of innovation, it is poised to maintain its leadership position in the metalworking industry and make a lasting impact on the global manufacturing landscape.

Company News & Blog

High-quality Corrugated Roll Making Machine for Efficient Production

Today, we are excited to announce the launch of the latest Corrugated Roll Making Machine by a leading machinery manufacturer. This new machine is set to revolutionize the production process for corrugated rolls, delivering enhanced efficiency and precision.The new Corrugated Roll Making Machine integrates state-of-the-art technology with a user-friendly design to offer a comprehensive solution for corrugated roll production. With its advanced features and high performance, this machine promises to meet the growing demand for top-quality corrugated rolls in various industries.This cutting-edge machine boasts a range of innovative capabilities, including high-speed operation, precise cutting and shaping, and minimal maintenance requirements. It is designed to streamline the production process, reduce downtime, and increase overall productivity, making it an indispensable asset for manufacturers in the corrugated packaging industry.The Corrugated Roll Making Machine is equipped with a user-friendly interface, allowing operators to easily configure settings, monitor performance, and troubleshoot any issues that may arise. Its intuitive controls and automated functions enable seamless operation, even for users with limited experience in roll production.In addition to its superior performance, this new machine is also designed with a focus on sustainability. It incorporates energy-efficient components and utilizes environmentally friendly materials, aligning with the company's commitment to reducing its environmental footprint and promoting sustainable manufacturing practices.As a leading manufacturer of machinery for the packaging industry, we have a strong track record of delivering innovative, high-quality solutions to our customers. With our extensive expertise and dedication to excellence, we are confident that the new Corrugated Roll Making Machine will exceed expectations and set new industry standards for roll production.Our company has been at the forefront of the packaging machinery market for over [number] years, and we have earned a reputation for delivering reliable, high-performance equipment that meets the evolving needs of our customers. With our commitment to innovation and customer satisfaction, we continue to push the boundaries of what is possible in roll making technology.The launch of the Corrugated Roll Making Machine represents a significant milestone for our company, as it reinforces our position as a leading provider of advanced machinery for the packaging industry. We are excited to introduce this game-changing product to our customers and are confident that it will provide them with a competitive advantage in their respective markets.In conclusion, the new Corrugated Roll Making Machine from the leading machinery manufacturer is set to revolutionize the production process for corrugated rolls. With its advanced technology, user-friendly design, and focus on sustainability, this machine promises to deliver unmatched efficiency and precision for roll production. We are proud to continue our tradition of innovation and look forward to the positive impact that this new machine will have on the packaging industry.

Metal Roof Roll Forming Equipment: Essential Equipment for Manufacturing Metal Roofs

Roll Forming Equipment Revolutionizing Metal Roofing IndustryMetal roofing has gained significant popularity in recent years, owing to its durability, longevity, and aesthetic appeal. To meet the growing demand for metal roofs, companies are constantly seeking innovative manufacturing solutions. Recognizing this need, a prominent industry player has developed state-of-the-art roll forming equipment that is set to revolutionize the metal roofing industry. In this article, we will explore the features of this cutting-edge technology and its potential implications for the market.The roll forming equipment, created by a renowned manufacturer, is specifically designed to produce high-quality metal roofing panels with precision and efficiency. This equipment consists of a series of rollers, dies, and controls that shape the metal sheets into desired profiles. With the ability to handle various types of metal, including steel and aluminum, this equipment ensures uniform panel dimensions and flawless surface finish.One of the key advantages of this roll forming technology is its ability to produce metal roofing panels in a continuous process. Unlike traditional methods that involve multiple production stages, the roll forming equipment eliminates the need for cutting, welding, and bending, saving both time and labor costs. This streamlined manufacturing process not only boosts efficiency but also ensures consistent product quality and reduces material waste.Furthermore, the roll forming equipment incorporates advanced computerized controls that enable operators to easily adjust the parameters and create customized roofing profiles. This user-friendly interface allows for quick setup and reduces the risk of human error. Moreover, the equipment can be integrated with other factory automation systems, enabling seamless production flow and enhanced productivity.The introduction of this roll forming equipment is expected to transform the metal roofing industry in multiple ways. Firstly, it will provide manufacturers with a competitive edge by increasing their production capacity and reducing lead times. This will enable them to meet the growing demand for metal roofs in a timely manner, without compromising quality.Secondly, the precision and consistency offered by this equipment will result in superior metal roofing panels. The elimination of manual processes reduces the risk of errors and ensures that every panel meets strict industry standards. This enhanced quality will not only meet customer expectations but also improve the overall reputation of metal roofing as a reliable and durable option.Additionally, this technology presents new opportunities for customization in the metal roofing market. With the ability to easily adjust the profile dimensions and designs, manufacturers can cater to a wider range of customer preferences. This flexibility will allow architects and builders to create unique roofing solutions that enhance the appearance of commercial and residential structures.Apart from the manufacturing benefits, the roll forming equipment also contributes to sustainability in the metal roofing industry. By minimizing material waste and optimizing production processes, it helps reduce a company's carbon footprint. Furthermore, metal roofs themselves are known for their eco-friendly properties, as they are often made from recycled materials and can be fully recycled at the end of their lifespan.In conclusion, the introduction of cutting-edge roll forming equipment for metal roofs promises to revolutionize the industry. Through its advanced technology, streamlined processes, and enhanced customization options, this equipment enables manufacturers to meet the increasing demand for metal roofs efficiently and effectively. Alongside improving production capacity and product quality, it also promotes sustainability in the construction sector. As the market continues to grow, this innovative equipment will undoubtedly play a crucial role in shaping the future of the metal roofing industry.

How to Choose the Right Steel Roll Forming Machine for Your Needs?

article:Color Steel Roll Forming Machine Shapes Global Construction IndustryThe global construction industry has been witnessing a significant boost in the past few years. With advanced construction techniques and increasing demand for durable infrastructure, the industry is constantly witnessing new innovations. One of the latest technologies that are gaining wide popularity is the Color Steel Roll Forming Machine.The Color Steel Roll Forming Machine is a highly sophisticated mechanical device that is used in the construction industry to manufacture various steel products that are used in building construction. The machine plays a vital role in shaping various roofing and cladding products that are not only durable but also aesthetically appealing.Leading the race of this advanced technology are some of the leading Color Steel Roll Forming Machine manufacturers, such as ___, who are committed to designing and developing machines that meet the highest quality standards. Their machines are designed to cater to the diverse needs of clients across various industries, including construction, automotive, and industrial.The Company, ____ has been in the business of manufacturing high-end roll forming machines for over 20 years. They specialize in designing and developing machines that are efficient, reliable, and deliver a high level of precision, flexibility, and accuracy. They have a team of highly qualified and skilled professionals who have expertise in the design and engineering of various types of roll forming machines.Their range of Color Steel Roll Forming Machines is designed to cater to the needs of clients across various verticals. The machines are equipped with the latest technology and are capable of producing high-quality steel products in large quantities. Some of the popular products manufactured using these machines include metal roofing sheets, wall cladding sheets, floor decking, tile profile sheets, etc.The company uses high-grade materials and superior quality components in the manufacturing of their machines. All the machines undergo rigorous quality checks and inspections before they are released to the market, ensuring that only the best machines reach their clients.The Company's manufacturing unit is equipped with state-of-the-art machinery and equipment that is used to produce machines that are not only efficient but also eco-friendly. The machines are designed to consume minimal energy, thereby reducing the carbon footprint and helping the environment.Apart from manufacturing Color Steel Roll Forming Machines, the Company also provides excellent after-sales support, including installation, training, and maintenance services. Their team of experienced technicians ensures that their clients receive timely assistance and support, whenever required.The demand for Color Steel Roll Forming Machines has been witnessing a steady rise in recent times, owing to the numerous benefits they offer. These machines are known for their accuracy, precision, flexibility, and efficiency, making them an ideal choice for businesses looking to boost their productivity and efficiency.With advanced technology and superior quality machines, companies like ____ are changing the face of the construction industry. Their machines are not only efficient but also contribute to sustainable development, by minimizing the impact on the environment.In conclusion, the Color Steel Roll Forming Machine is a highly advanced mechanical device that is changing the dynamics of the construction industry. Leading manufacturers like ____ are using the latest technology and superior quality materials to produce machines that cater to the diverse needs of clients across various industries. These machines are efficient, reliable, and eco-friendly, making them a popular choice for businesses looking to boost their productivity and efficiency. The future of the construction industry looks promising, with innovative technologies like these at the forefront.

High-Quality Roof Sheet or Zinc Forming Machine for Sale

Roof Sheet Or Zink Forming Machine, a leading manufacturing company in the field of metal forming machinery, has been making waves in the industry with their innovative and high-quality products. Specializing in the production of roof sheet and zink forming machines, the company has a proven track record of delivering state-of-the-art equipment that meets the needs of their clients.With a strong dedication to research and development, Roof Sheet Or Zink Forming Machine has been at the forefront of technological advancements in their field. The company's team of engineers and designers are constantly pushing the boundaries of what is possible, resulting in cutting-edge machinery that is both reliable and efficient. Their commitment to innovation has earned them a reputation as a trusted provider of metal forming solutions.One of the key factors that sets Roof Sheet Or Zink Forming Machine apart from its competitors is its focus on quality. The company uses only the best materials and components in the production of their machines, ensuring that they are durable and built to last. Each machine undergoes rigorous testing and quality control measures to guarantee that it meets the highest standards before it is delivered to the customer.In addition to their dedication to quality, Roof Sheet Or Zink Forming Machine is also known for its excellent customer service. The company works closely with each client to understand their specific needs and requirements, and then customizes their machines to meet those needs. This personalized approach has helped the company build long-lasting relationships with its clients, many of whom are repeat customers.Roof Sheet Or Zink Forming Machine's commitment to excellence extends beyond the products themselves. The company also provides comprehensive training and support to ensure that their clients are able to operate and maintain their machines effectively. This level of ongoing support has been a key factor in the company's success, as it has helped their clients maximize the value of their investments in Roof Sheet Or Zink Forming Machine's products.With a strong focus on quality, innovation, and customer satisfaction, Roof Sheet Or Zink Forming Machine has positioned itself as a leader in the metal forming machinery industry. The company's dedication to excellence and its proven track record of delivering top-notch products have set it apart from its competitors. As the demand for high-quality metal forming solutions continues to grow, Roof Sheet Or Zink Forming Machine is well-positioned to meet the needs of its clients and to continue to thrive in the industry.

Spacious and Durable Permanent Structure Garden Tent with Fire Rating: Grade DB1

Title: The Versatility and Value of Permanent Structure Garden TentsIntroduction:In today's fast-paced world, where outdoor events are becoming increasingly popular, the demand for versatile, durable, and eye-catching structures like permanent garden tents is on the rise. These structures not only provide a unique outdoor experience but also offer shelter, space, and unlimited customization possibilities. In this blog, we will explore the features, benefits, and uses of permanent structure garden tents made using high-speed steel roof truss C Z purline making machinery, ensuring their enduring quality and functionality.Size and Steel Structure:One of the key advantages of permanent structure garden tents is their spaciousness. Available in a variety of sizes, the 30M X 50M permanent garden tent provides ample room for any event or gathering. To ensure utmost reliability and durability, the tents are constructed using high-quality Q235 steel, known for its strength and resilience. This steel structure guarantees the safety of occupants and guards against adverse weather conditions, making the garden tent suitable for long-term installations.Membrane Material and Fire Rating:The membrane material used in the construction of permanent structure garden tents is PVDF, which offers exceptional visual appeal and long-lasting performance. PVDF membranes provide high resistance to UV radiation, chemicals, and extreme temperatures, making them ideal for outdoor use. Additionally, these membranes have a fire rating of Grade DB1, ensuring the safety of all occupants. This critical feature makes permanent garden tents suitable for various events, including concerts, exhibitions, weddings, and corporate gatherings.Delivery Time, Port, and Payment Options:Understanding the time constraints that event organizers often face, the delivery time for permanent structure garden tents is 20-30 days. Quick and efficient transportation from the warehouse to the desired location is made possible by convenient access to Huangpu or Nansha ports. To facilitate easy transactions, payments for the tent can be made via T/T (Telegraphic Transfer) or Western Union, providing flexibility and compatibility with various international payment systems.Versatility and Customization:Permanent structure garden tents offer endless possibilities for customization and adaptability to meet specific event requirements. With the help of high-speed steel roof truss C Z purline making machinery, these tents can be easily transformed into outdoor venues or temporary shelter solutions. The machinery enables the construction of strong and durable frameworks that can support lighting fixtures, stage setups, audio-visual equipment, or any other desired fixtures, ensuring a seamless experience for both organizers and attendees.Conclusion:Permanent structure garden tents have become a must-have solution for event organizers, given their versatility, durability, and customization potential. Constructed using high-quality Q235 steel and PVDF membrane material, these tents offer a safe and comfortable environment for various events. With a quick delivery time and flexible payment options, they are a practical choice for anyone looking for a long-term or temporary outdoor shelter solution. By utilizing high-speed steel roof truss C Z purline making machinery, these tents can be tailored to unique requirements, transforming any space into an extraordinary event venue.

Metal Slitting Line for Sale: High-Quality Machines in Various Gauges

Steel Slitting Line Machine Manufacturer: RISHBINRISHBIN is one of the top steel slitting line machine manufacturers in the industry, providing high-quality slitting line machines to customers worldwide. The company has been in the business for over 20 years, establishing itself as a reliable and trustworthy supplier of metal slitting line machines of different gauges.Metal slitting or steel slitting refers to the process of cutting large rolls or coils of sheet metal into narrower strips or coils of specific widths. Steel slitting line machines are essential tools in many industries, such as automotive, construction, and manufacturing, that require large amounts of sheet metal products in varying sizes for their operations.RISHBIN's metal slitting line machines are built with precision engineering and state-of-the-art technology, making them the most efficient and reliable slitting line machines in the market. The company offers three types of gauges of slitting line machines to meet the diverse needs of its clients.The light gauge slitting line machine is ideal for thin sheets of metal that require high-speed precision cutting. This machine is also efficient in handling delicate materials such as aluminum and brass.The medium gauge slitting line machine is designed for cutting thicker metal sheets used in the construction and manufacturing industries. This machine is fast, accurate, and efficient in handling sheets with thicknesses between 0.3 mm and 3.2 mm.Lastly, the heavy gauge slitting line machine is intended for the largest and thickest sheets of metal used in heavy industries. This powerful machine operates at high speeds while maintaining maximum precision, making it ideal for cutting large volumes of metal sheets with thicknesses up to 20 mm.At RISHBIN, the team of engineers and technicians works closely with clients to design and build customized metal slitting line machines that meet their specific needs and requirements. The company's machines are equipped with advanced features such as Automatic Gauge Control, Automatic Edge Control, and Automatic Tension Control, ensuring optimal precision and efficiency in the metal cutting process.RISHBIN's commitment to quality, innovation, and service has made it one of the most sought-after suppliers of metal slitting line machines in the industry. The company provides comprehensive after-sales support, including installation, training, and maintenance services, to ensure the sustainability and longevity of its machines.In conclusion, RISHBIN is a trusted and reliable supplier of metal slitting line machines of different gauges. Its precision-engineered, state-of-the-art machines offer maximum efficiency, accuracy, and speed in the metal cutting process. Clients can rely on RISHBIN for customized solutions and comprehensive after-sales support for their metal processing needs. Visit RISHBIN's website at steelslitter.com to learn more about its products and services.

Top Ag Panel Roll Forming Machine: What You Need to Know

Ag Panel Roll Former is a leading manufacturer of roll forming machines for the agricultural industry. Their innovative equipment is designed to streamline the process of producing high-quality metal panels used in the construction of agricultural buildings, including barns, silos, and storage facilities. With a focus on precision engineering and durability, Ag Panel Roll Former has established itself as a trusted provider of roll forming solutions for farmers and agricultural contractors around the world.The company's roll forming machines are known for their efficiency and reliability, allowing agricultural businesses to increase their productivity and reduce overall production costs. By automating the process of forming metal panels, Ag Panel Roll Former's machines enable farmers to meet the growing demand for durable and cost-effective building materials.In a recent press release, Ag Panel Roll Former announced the launch of their newest roll forming machine, the Ag Panel 3000. This state-of-the-art equipment is designed to meet the evolving needs of the agricultural industry, offering enhanced speed, precision, and versatility. With the Ag Panel 3000, farmers and agricultural contractors can produce a wide range of metal panels with ease, including corrugated panels, standing seam panels, and custom profiles tailored to their specific building requirements.The Ag Panel 3000 is equipped with advanced features such as quick-change tooling, allowing users to switch between panel profiles with minimal downtime. This flexibility is essential for agricultural businesses that need to adapt to changing project specifications and tight deadlines. Additionally, the machine's computerized controls and intuitive interface make it easy for operators to monitor and adjust the production process, ensuring consistent quality and minimizing material waste.The launch of the Ag Panel 3000 represents Ag Panel Roll Former's commitment to continuous innovation and customer satisfaction. By incorporating feedback from their extensive network of agricultural clients, the company has developed a roll forming machine that addresses the unique challenges of building construction in the agricultural sector. With its robust construction and advanced technology, the Ag Panel 3000 is set to become a valuable asset for farmers looking to expand their operations or upgrade their existing facilities.In addition to their cutting-edge roll forming machines, Ag Panel Roll Former offers comprehensive support services to help customers maximize the performance and longevity of their equipment. From installation and training to ongoing maintenance and troubleshooting, the company's team of experts is dedicated to ensuring that agricultural businesses can rely on their roll forming machines for years to come.With a focus on sustainable farming practices, Ag Panel Roll Former is also committed to minimizing the environmental impact of their operations. By promoting the use of metal panels made from recycled materials and optimizing the energy efficiency of their machines, the company is contributing to the long-term sustainability of the agricultural industry.As the demand for durable and cost-effective building materials continues to grow, Ag Panel Roll Former is poised to play a crucial role in meeting the needs of the agricultural sector. With their proven track record of innovation and customer satisfaction, the company is well-positioned to remain a leader in the roll forming industry for years to come.

High-Quality Cable Tray Forming Machine for Efficient Cable Management

Cable Tray Forming Machine Powering the Future of Industrial ManufacturingCable tray forming machines are revolutionizing the way industrial manufacturing companies produce cable management systems. These machines are a crucial component in the production of cable trays, which are used to support insulated electrical cables for power distribution and communication. With the increasing demand for cable management systems in various industries, the need for efficient and high-quality cable tray forming machines has become paramount.{Company Name}, a leading manufacturer of industrial machinery, has been at the forefront of producing state-of-the-art cable tray forming machines. With over 20 years of experience in the industry, {Company Name} has established itself as a reliable and innovative provider of machinery for the manufacturing sector.The cable tray forming machine manufactured by {Company Name} boasts a range of advanced features that set it apart from the competition. Equipped with cutting-edge technology and precision engineering, this machine is capable of producing cable trays of various sizes and specifications with remarkable speed and accuracy. Furthermore, its user-friendly interface and automated controls make it easy to operate and maintain, reducing the need for extensive training and technical expertise.In addition to its high-performance capabilities, the cable tray forming machine from {Company Name} is also designed with energy efficiency in mind. By minimizing energy consumption and optimizing production processes, this machine helps manufacturing companies reduce their carbon footprint and operational costs, contributing to a more sustainable and environmentally friendly industrial sector.One of the key advantages of using {Company Name}'s cable tray forming machine is its versatility. Whether it's for the automotive, construction, telecommunications, or energy sectors, this machine can adapt to the specific requirements of different industries, making it an ideal solution for manufacturers with diverse production needs.Moreover, {Company Name} provides comprehensive technical support and after-sales services to ensure that their customers can maximize the potential of the cable tray forming machine. With a team of skilled engineers and technicians, the company offers training programs, maintenance services, and troubleshooting assistance to help clients overcome any operational challenges and keep their production running smoothly.As the demand for cable management systems continues to grow across various industries, the role of cable tray forming machines in the manufacturing process has become increasingly vital. By partnering with {Company Name} and investing in their cutting-edge machinery, industrial manufacturers can enhance their production capabilities, increase efficiency, and stay competitive in the ever-evolving market.In conclusion, the cable tray forming machine from {Company Name} exemplifies the innovative spirit and commitment to excellence that has made the company a trusted name in the industrial machinery sector. With its advanced technology, energy-efficient design, and exceptional versatility, this machine is poised to play a crucial role in shaping the future of industrial manufacturing. As more companies recognize the benefits of using this state-of-the-art equipment, the industry can look forward to a more efficient, sustainable, and productive future powered by the cable tray forming machine from {Company Name}.

Advanced Metal Profile Machine for Precise and Efficient Production

Metal Profile Machine Enhances Precision and Efficiency in Company’s ProductionIn today’s competitive manufacturing industry, precision and efficiency are essential factors for success. With the introduction of the Metal Profile Machine at {company name}, the company has taken a significant step towards enhancing its production capabilities and meeting the demands of its clients more effectively.The Metal Profile Machine is a state-of-the-art equipment that has revolutionized the way {company name} fabricates metal profiles for various industrial applications. This advanced machine is equipped with cutting-edge technology that allows for high levels of precision and accuracy in shaping and cutting metal sheets. The result is a more efficient and cost-effective manufacturing process that ultimately benefits both the company and its customers.The implementation of the Metal Profile Machine aligns with {company name}’s commitment to staying at the forefront of technological advancements in the industry. With a focus on innovation and continuous improvement, the company has always sought out the latest tools and equipment to streamline its operations and deliver the highest quality products to its clients.The Metal Profile Machine has significantly enhanced the company’s ability to meet the specific requirements of its customers. With the capability to work with a wide range of metal materials and produce complex profiles with tight tolerances, {company name} can now take on a broader scope of projects and tailor its offerings to the unique needs of each client.Furthermore, the improved precision of the Metal Profile Machine has led to a reduction in material waste, as well as a decrease in the need for manual rework. This not only contributes to a more sustainable manufacturing process but also allows {company name} to optimize its resources and minimize production costs.In addition to the operational benefits, the Metal Profile Machine has also bolstered {company name}’s reputation for delivering top-quality products. The enhanced precision and consistency in the fabrication of metal profiles has resulted in a higher level of product reliability and performance, ultimately leading to greater customer satisfaction and loyalty.Mr. John Smith, the CEO of {company name}, expressed his enthusiasm for the acquisition of the Metal Profile Machine, stating, "We are thrilled to have this cutting-edge technology as part of our manufacturing capabilities. The Metal Profile Machine not only elevates our operational efficiency but also allows us to exceed the expectations of our clients in terms of quality and customization."The addition of the Metal Profile Machine has also opened up new opportunities for {company name} to explore and expand its product offerings. With the ability to produce intricate and bespoke metal profiles, the company is now able to cater to a wider range of industries, including automotive, aerospace, construction, and more.Moving forward, {company name} plans to further leverage the capabilities of the Metal Profile Machine to continue raising the bar in the metal fabrication sector. By harnessing the machine’s potential to innovate and optimize its production processes, the company aims to solidify its position as a leader in the industry and to be the go-to choice for clients seeking superior metal profiles.In conclusion, the introduction of the Metal Profile Machine at {company name} has been a game-changer for the company, allowing it to achieve new levels of precision, efficiency, and customization in its production processes. As the company continues to harness the full potential of this cutting-edge equipment, it is poised to set new standards in the manufacturing industry and deliver exceptional value to its clients.

Pros and Cons of All-In-One vs. Multiple Single Layer Roll Forming Machines: A Comprehensive Comparison

, Multiple Roll Forming Machines, All-in-one Roll Forming Machine, Double layer Roll Forming Machine, Roll Forming Machinery.When it comes to roll forming, there are a few different options to consider. One decision that needs to be made is whether to choose an all-in-one roll forming machine or multiple single layer roll forming machines. Both options have their pros and cons, so it ultimately depends on the specific needs and preferences of the user.Single layer roll forming machines are a popular choice for many manufacturers. These machines are designed to create a continuous sheet of metal by bending it into a certain shape. One of the advantages of using a single layer roll forming machine is the ability to produce a high volume of products quickly and efficiently. Since the machine only focuses on one layer at a time, it's easier to control the quality of each product and ensure that each one is consistent.Another advantage of using a single layer roll forming machine is the ability to customize the process based on the specific needs and materials being used. These machines are often designed to be highly flexible, allowing for adjustments to be made based on the thickness and type of material being used.However, one of the downsides of using a single layer roll forming machine is the need for multiple machines if a manufacturer needs to produce multiple layers. This can be a disadvantage if a manufacturer is trying to minimize the number of machines being used in their production process.On the other hand, all-in-one roll forming machines are designed to be highly versatile and efficient. These machines are capable of producing multiple layers of metal at once, which can help streamline the production process. Additionally, all-in-one roll forming machines are often designed to be highly automated, which can help reduce the need for labor and increase overall efficiency.One of the disadvantages of using an all-in-one roll forming machine is the potential for decreased quality control. Since these machines are designed to focus on multiple layers at once, it can be more difficult to ensure that each product is consistent and meets the desired quality standards.Another potential disadvantage of using an all-in-one roll forming machine is the cost. These machines are typically more expensive than single layer roll forming machines, which can be a disadvantage for smaller manufacturers or those with limited budgets.Finally, double layer roll forming machines are another option to consider. These machines are designed to produce two layers of metal at once, which can help increase production efficiency and reduce the need for multiple machines. However, like all-in-one roll forming machines, double layer roll forming machines can be more expensive and may have lower quality control.Ultimately, the decision to choose between an all-in-one roll forming machine and multiple single layer roll forming machines will depend on a variety of factors, including the specific needs and preferences of the manufacturer. Both options have their advantages and disadvantages, so manufacturers should carefully consider their options before making a final decision.