Top Quality Purlin Forming Machine for Construction Projects

By:Admin

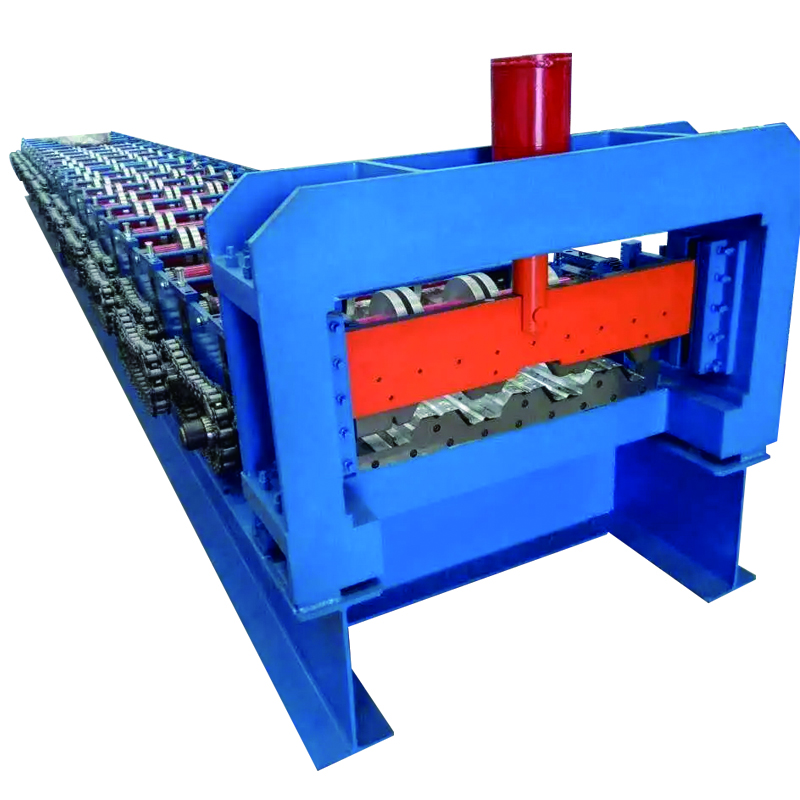

In a rapidly growing construction industry, the demand for efficient and high-quality building materials and equipment has never been greater. Purlin forming machines have emerged as a game-changer in the industry, offering a cost-effective and time-saving solution for producing purlins, which are essential structural elements in building construction. With the introduction of the innovative Purlin Forming Machine by an industry-leading company, construction projects are now poised to benefit from increased efficiency, precision, and overall productivity.

The Purlin Forming Machine, developed by {Company}, is a state-of-the-art piece of equipment designed to manufacture purlins of various sizes and configurations with unparalleled speed and accuracy. Its advanced technology and seamless operation make it an indispensable tool for modern construction projects, enabling builders and contractors to meet tight deadlines and deliver high-quality structures.

The versatility of the Purlin Forming Machine allows it to produce a wide range of purlin profiles, including C, Z, and U shapes, to suit different construction requirements. This adaptability makes it ideal for use in various building applications, from residential housing to commercial and industrial complexes. Furthermore, the machine's automated process minimizes human error, resulting in consistently uniform and precise purlins, which are essential for ensuring the structural integrity and stability of buildings.

The efficiency of the Purlin Forming Machine significantly reduces material waste, as it can produce purlins of precise lengths and dimensions, thereby optimizing the use of resources and cutting down on construction costs. Additionally, its high production capacity allows for large volumes of purlins to be manufactured in a short period, making it an invaluable asset for construction projects with tight schedules.

{Company} has been at the forefront of innovation in the construction equipment industry for years. With a strong commitment to research and development, the company has continuously strived to create cutting-edge solutions that address the evolving needs of the construction sector. The Purlin Forming Machine is a testament to the company's dedication to excellence and a reflection of its vision to drive progress and efficiency in the construction industry.

The Purlin Forming Machine is designed for ease of use and requires minimal maintenance, making it a cost-effective investment for construction companies. Its user-friendly interface and intuitive controls ensure that operators can quickly learn to operate the machine with ease, minimizing downtime and maximizing productivity on construction sites. Additionally, {Company} provides comprehensive training and support to clients, ensuring that they can fully harness the capabilities of the machine for their projects.

In line with its commitment to sustainability, {Company} has also incorporated energy-efficient features in the Purlin Forming Machine to minimize its environmental impact. By optimizing energy usage and reducing emissions, the machine aligns with the industry's growing focus on eco-friendly construction practices, offering a responsible and forward-thinking solution for builders and developers.

As the construction industry continues to evolve with technological advancements, the Purlin Forming Machine represents a significant leap forward in the quest for efficiency, precision, and sustainability in building construction. Its impact on the industry is poised to be transformative, empowering construction companies to meet the demands of modern infrastructure development with confidence and ingenuity.

With the introduction of the Purlin Forming Machine, {Company} has set a new standard for excellence in the construction equipment market, reinforcing its position as a leader in innovation and reliability. As construction projects worldwide seek to enhance their efficiency and productivity, the Purlin Forming Machine stands out as a groundbreaking solution that is poised to shape the future of building construction for years to come.

Company News & Blog

High-Quality Metal Slitting Line Machines for Sale in Different Gauges

When it comes to metal processing, a slitting line is an essential piece of equipment that is used to cut large coils of metal into narrower widths. A metal slitting line involves a series of operations that include uncoiling, feeding the metal strip through a set of knives, slitting the metal strip into desired widths, and recoiling the strips. The slitting process is widely used in various industries, including automotive, construction, and manufacturing.If you are looking for a high-quality metal slitting line for your business needs, RISHBIN is the right place to go. As one of the leading slitting line manufacturers, RISHBIN offers a range of metal slitting lines that are designed to meet different gauge requirements: light, medium, and heavy gauge.Heavy Gauge Slitting LineA heavy gauge slitting line is typically used for cutting thicker metal strips that range from 2mm to 16mm in thickness. It is an ideal option for industries that require thick materials, such as shipbuilding, bridge construction, and oil and gas pipelines. The heavy gauge slitting line features advanced technology that enables it to handle heavy-duty materials with ease.The heavy gauge slitting line from RISHBIN is designed to handle coils of up to 30 tons and widths of up to 2200mm. The machine features a hydraulic coil car that makes loading and unloading of coils easier and safer. The machine also has a decoiler that ensures smooth feeding of the material to the slitter head.The slitter head of the heavy gauge slitting line features an advanced design that enables it to slit thick materials with high precision. The machine has multiple knife sets that can be easily adjusted to accommodate different width requirements. The slitter head also features a powerful motor that ensures perfect slitting even at high speeds.Once the metal strip has been slit into the desired width, the machine recoils the strips. The recoiling process is also designed to handle heavy-gauge materials without causing any damage. The recoiler is equipped with a tensioning system that ensures uniform rewinding of the strips.In conclusion, a heavy gauge slitting line is an essential machine for any business that requires thick materials. The heavy gauge slitting line from RISHBIN is one of the best on the market, featuring advanced technology that ensures high precision and efficiency. If you are interested in purchasing a heavy gauge slitting line, RISHBIN is the right place to look.

Top Quality Purlin Forming Machine for Construction Projects

Purlin Forming Machine: Revolutionizing the Construction IndustryIn a rapidly growing construction industry, the demand for efficient and high-quality building materials and equipment has never been greater. Purlin forming machines have emerged as a game-changer in the industry, offering a cost-effective and time-saving solution for producing purlins, which are essential structural elements in building construction. With the introduction of the innovative Purlin Forming Machine by an industry-leading company, construction projects are now poised to benefit from increased efficiency, precision, and overall productivity.The Purlin Forming Machine, developed by {Company}, is a state-of-the-art piece of equipment designed to manufacture purlins of various sizes and configurations with unparalleled speed and accuracy. Its advanced technology and seamless operation make it an indispensable tool for modern construction projects, enabling builders and contractors to meet tight deadlines and deliver high-quality structures.The versatility of the Purlin Forming Machine allows it to produce a wide range of purlin profiles, including C, Z, and U shapes, to suit different construction requirements. This adaptability makes it ideal for use in various building applications, from residential housing to commercial and industrial complexes. Furthermore, the machine's automated process minimizes human error, resulting in consistently uniform and precise purlins, which are essential for ensuring the structural integrity and stability of buildings.The efficiency of the Purlin Forming Machine significantly reduces material waste, as it can produce purlins of precise lengths and dimensions, thereby optimizing the use of resources and cutting down on construction costs. Additionally, its high production capacity allows for large volumes of purlins to be manufactured in a short period, making it an invaluable asset for construction projects with tight schedules.{Company} has been at the forefront of innovation in the construction equipment industry for years. With a strong commitment to research and development, the company has continuously strived to create cutting-edge solutions that address the evolving needs of the construction sector. The Purlin Forming Machine is a testament to the company's dedication to excellence and a reflection of its vision to drive progress and efficiency in the construction industry.The Purlin Forming Machine is designed for ease of use and requires minimal maintenance, making it a cost-effective investment for construction companies. Its user-friendly interface and intuitive controls ensure that operators can quickly learn to operate the machine with ease, minimizing downtime and maximizing productivity on construction sites. Additionally, {Company} provides comprehensive training and support to clients, ensuring that they can fully harness the capabilities of the machine for their projects.In line with its commitment to sustainability, {Company} has also incorporated energy-efficient features in the Purlin Forming Machine to minimize its environmental impact. By optimizing energy usage and reducing emissions, the machine aligns with the industry's growing focus on eco-friendly construction practices, offering a responsible and forward-thinking solution for builders and developers.As the construction industry continues to evolve with technological advancements, the Purlin Forming Machine represents a significant leap forward in the quest for efficiency, precision, and sustainability in building construction. Its impact on the industry is poised to be transformative, empowering construction companies to meet the demands of modern infrastructure development with confidence and ingenuity.With the introduction of the Purlin Forming Machine, {Company} has set a new standard for excellence in the construction equipment market, reinforcing its position as a leader in innovation and reliability. As construction projects worldwide seek to enhance their efficiency and productivity, the Purlin Forming Machine stands out as a groundbreaking solution that is poised to shape the future of building construction for years to come.

High-Quality Aluminum Profile Bending Machine for CNC Applications

In recent years, the demand for high-quality aluminum profile bending machines has been steadily increasing in various industries such as construction, manufacturing, and automotive. As a response to this growing demand, (Company name) has introduced a cutting-edge CNC aluminum profile bending machine that is set to revolutionize the industry.The CNC aluminum profile bending machine is a state-of-the-art piece of equipment that is designed to bend aluminum profiles with precision and efficiency. The machine is equipped with advanced CNC technology that allows for accurate and repeatable bending of aluminum profiles, resulting in high-quality finished products. This is especially crucial in industries such as construction and manufacturing where precision and quality are of utmost importance.One of the key features of the CNC aluminum profile bending machine is its flexibility. The machine is capable of bending aluminum profiles of various shapes and sizes, making it suitable for a wide range of applications. Additionally, the machine is designed to be user-friendly, with intuitive controls and easy programming, allowing for seamless operation by both experienced and novice operators.In addition to its precision and flexibility, the CNC aluminum profile bending machine is also known for its speed and efficiency. The machine is capable of bending aluminum profiles at a rapid pace, thereby increasing productivity and reducing lead times. This is essential for businesses looking to meet tight deadlines and stay ahead of the competition.(Company name) takes pride in offering products that are not only innovative but also reliable and durable. The CNC aluminum profile bending machine is no exception. It is built with high-quality materials and components, ensuring its longevity and robust performance even in the most demanding working environments. This makes it a valuable investment for businesses looking for a long-term solution for their aluminum profile bending needs.Furthermore, (company name) provides comprehensive technical support and after-sales service for its CNC aluminum profile bending machine. This includes installation, training, maintenance, and troubleshooting assistance, ensuring that customers can maximize the potential of the machine and minimize any downtime.The introduction of the CNC aluminum profile bending machine by (company name) is poised to have a significant impact on the industry. With its cutting-edge technology, precision, flexibility, and efficiency, the machine is set to meet the evolving demands of businesses across various sectors. It is expected to streamline the aluminum profile bending process, improve productivity, and elevate the quality of finished products.In conclusion, the CNC aluminum profile bending machine by (company name) represents a significant advancement in the industry. Its innovative features, coupled with the company's commitment to quality and customer support, make it a game-changer for businesses looking to enhance their aluminum profile bending capabilities. As the industry continues to evolve, (company name) remains at the forefront, delivering solutions that exceed expectations and set new standards for excellence.

Efficient Roll Forming Machine for Color Steel Glazed Roofing Sheets Unveiled

[Dating], [Geographical Location] - The global construction industry is witnessing a major technological breakthrough as [Company Name], a leading manufacturer of machinery and equipment, introduces its state-of-the-art Color Steel Glazed Roofing Sheet Roll Forming Machine. This innovative product is set to revolutionize the production of glazed roofing sheets, enabling builders and contractors to enhance the durability, aesthetic appeal, and cost-effectiveness of their projects.The Color Steel Glazed Roofing Sheet Roll Forming Machine, designed and manufactured by [Company Name], incorporates cutting-edge technology and premium-quality materials to deliver outstanding performance and unparalleled efficiency. The machine is equipped with advanced automation systems and intelligent controls, ensuring precise and accurate sheet formation. This eliminates human error and reduces production time, thereby enhancing productivity and overall project completion rates.With the global construction industry being increasingly mindful of sustainable practices, the Color Steel Glazed Roofing Sheet Roll Forming Machine offers a sustainable solution. It utilizes recycled materials and minimizes waste generation during the production process. This eco-friendly approach not only aligns with environmental regulations but also positions builders and contractors as responsible industry players, meeting the expectations of environmentally conscious consumers.Additionally, the Color Steel Glazed Roofing Sheet Roll Forming Machine caters to the rising demand for energy-efficient buildings. The machine is engineered to create roofing sheets that effectively reflect heat, reducing the need for excessive cooling measures. This not only lowers energy consumption but also translates into substantial cost savings for building owners. Furthermore, the glazed roofing sheets produced by this machine offer superior insulation, enhancing the overall thermal performance of structures.[Company Name] is renowned for delivering cutting-edge solutions in the construction machinery sector, with a history of successful projects and a growing global client base. The company's commitment to quality and innovation has earned it a reputation as an industry leader. By introducing the Color Steel Glazed Roofing Sheet Roll Forming Machine, [Company Name] reaffirms its dedication to providing market-leading products that meet the evolving needs of the construction industry.The machine's user-friendly interface and streamlined operation make it accessible to both experienced manufacturers and newcomers to the industry. It offers customizable settings and efficient production capabilities, ensuring flexibility and versatility for a wide range of roofing sheet designs. The machine's robust construction and reliable performance guarantee longevity and durability, minimizing maintenance and replacement costs for users.Furthermore, [Company Name]'s dedication to customer satisfaction extends beyond the sale of the Color Steel Glazed Roofing Sheet Roll Forming Machine. The company provides comprehensive training programs and ongoing technical support to ensure users can fully utilize the machine's capabilities. This commitment to empowering its clients with the knowledge and resources required to maximize productivity sets [Company Name] apart from its competitors.As the global construction industry continues to grow and evolve, [Company Name] remains at the forefront of technological advancements. With the introduction of the Color Steel Glazed Roofing Sheet Roll Forming Machine, the company is empowering builders and contractors to construct sustainable, energy-efficient, and visually appealing structures. This groundbreaking product reaffirms [Company Name]'s position as a leading manufacturer of machinery and equipment, committed to driving innovation and improving the construction industry as a whole.In conclusion, the Color Steel Glazed Roofing Sheet Roll Forming Machine introduced by [Company Name] is set to revolutionize the production of glazed roofing sheets, providing builders and contractors with a sustainable, energy-efficient, and cost-effective solution. The machine's cutting-edge technology, eco-friendly approach, and comprehensive customer support make it an essential asset for companies looking to stay ahead in an ever-evolving industry. [Company Name]'s commitment to delivering innovative solutions further cements its reputation as a global leader in the construction machinery sector.

High-Quality Roll Forming Machine for Tile Production

[Company Name], a leading manufacturer of roll forming machines, has recently unveiled its latest innovation in the form of the high-performance Tile Roll Forming Machine. This new machine is designed to meet the increasing demand for efficient and precise roll forming of various types of tiles used in construction and roofing applications.The Tile Roll Forming Machine from [Company Name] is built with advanced technology and features a robust and durable structure to ensure long-term performance and reliability. It is equipped with precision rollers and forming dies that can produce high-quality tiles with tight tolerances and consistent dimensions. This machine is capable of forming a wide range of tile profiles, including corrugated, trapezoidal, and custom designs, making it suitable for diverse roofing and cladding requirements.One of the key highlights of this Tile Roll Forming Machine is its user-friendly design and intuitive controls, which allow for easy setup and operation. The machine can be quickly adjusted to accommodate different tile specifications, and it is equipped with a high-speed production capability to meet the demands of large-scale roofing projects. Additionally, the machine is equipped with safety features and protective guards to ensure the well-being of operators during operation.In line with [Company Name]'s commitment to innovation and customer satisfaction, the Tile Roll Forming Machine is also supported by a comprehensive after-sales service and technical support. The company provides training and technical assistance to customers to ensure proper operation and maintenance of the machine, as well as prompt availability of spare parts and consumables."We are excited to introduce our new Tile Roll Forming Machine, which is the result of extensive research and development to address the specific needs of the roofing and construction industry," said [Spokesperson Name], the CEO of [Company Name]. "This machine is designed to deliver high-quality and cost-effective solutions for producing various types of tiles, and we are confident that it will bring significant value to our customers."The introduction of the Tile Roll Forming Machine is expected to enhance [Company Name]'s position as a leading provider of roll forming solutions for the construction and building materials sector. The company has a proven track record of delivering innovative and reliable machines that cater to the evolving needs of the industry, and the new Tile Roll Forming Machine further strengthens its product portfolio.With its advanced features, efficient performance, and comprehensive support, the Tile Roll Forming Machine from [Company Name] is poised to set a new benchmark for tile roll forming technology and contribute to the advancement of the construction industry. This latest innovation reflects the company's dedication to excellence and its commitment to empowering customers with high-performance solutions.For more information about the Tile Roll Forming Machine and other roll forming solutions offered by [Company Name], interested parties can visit the company's website or contact their sales representatives for inquiries and consultations.About [Company Name]:[Company Name] is a leading manufacturer of roll forming machines, serving the construction, automotive, and other industries with innovative and reliable solutions. With a strong focus on technology and customer satisfaction, the company designs and manufactures a wide range of roll forming machines to meet the specific needs of its diverse clientele. Backed by a team of skilled professionals and a commitment to quality, [Company Name] continues to lead the way in roll forming technology and solutions.

Ultimate Guide to Purlin Roll Forming: Everything You Need to Know

Purlin Roll Forming Machines: Revolutionizing the Steel Construction IndustryPurlin roll forming machines have revolutionized the steel construction industry, offering a more efficient and cost-effective way to produce high-quality purlins. With the advancement of technology, these machines have become an essential tool for companies looking to streamline their production processes and improve their bottom line.{} is a leading manufacturer of purlin roll forming machines, offering a wide range of products to meet the diverse needs of the steel construction industry. With a strong focus on innovation and quality, the company has established itself as a trusted partner for businesses looking to enhance their manufacturing capabilities.The purlin roll forming machines developed by {} are designed to offer precision and efficiency, enabling companies to produce purlins of various shapes and sizes with minimal waste. The company's commitment to research and development has led to the creation of cutting-edge technology that has set new standards in the industry.One of the key advantages of {}'s purlin roll forming machines is their versatility. These machines can be customized to meet specific production requirements, allowing businesses to adapt to changing market demands and stay ahead of the competition. With the ability to produce a wide range of purlin profiles, companies can take on a diverse range of projects and expand their market reach.In addition to their versatility, {}'s purlin roll forming machines are known for their durability and reliability. Built to withstand the rigors of heavy-duty production, these machines offer long-term value and performance, making them a sound investment for businesses of all sizes.The environmental impact of manufacturing processes is also a growing concern for businesses. {}'s purlin roll forming machines are designed to minimize waste and energy consumption, helping companies reduce their carbon footprint and operate more sustainably. By investing in these machines, businesses can demonstrate their commitment to environmental responsibility while also benefiting from reduced operational costs.Another key benefit of {}'s purlin roll forming machines is their ease of use. With user-friendly controls and intuitive interfaces, these machines are accessible to operators of all skill levels. This makes it easier for businesses to train their staff and integrate new technology into their production processes, ensuring a seamless transition and minimal downtime.As the steel construction industry continues to evolve, the demand for purlin roll forming machines is expected to grow. With their ability to improve efficiency, reduce costs, and enhance quality, these machines are poised to become a standard feature in modern manufacturing facilities. By partnering with a trusted supplier like {}, businesses can access the latest advancements in purlin roll forming technology and position themselves for success in a competitive market.In conclusion, purlin roll forming machines have emerged as a game-changer for the steel construction industry, offering a range of benefits that can significantly impact a company's bottom line. With {}'s commitment to innovation and quality, businesses can access cutting-edge technology that is designed to improve efficiency, reduce waste, and enhance sustainability. As the industry continues to embrace these advancements, purlin roll forming machines are set to become an essential tool for companies looking to stay ahead of the curve and maximize their potential.

Quality Light Steel Roll Forming Machine for Sale - Get Your Project Done Right!

In recent years, there has been a growing demand for light steel roll forming machines in the construction industry. These machines are used to produce high-quality, precise and durable light steel frames, which are then used in various construction projects. One company that has been at the forefront of this technology is {}. With their state-of-the-art technology and innovative solutions, they have been providing their customers with top-notch light steel roll forming machines that have been revolutionizing the construction industry.{} has been in the business for over a decade, specializing in the design, manufacturing, and distribution of light steel roll forming machines. They have a team of highly skilled engineers and technicians who are dedicated to developing cutting-edge technology that meets the needs of their clients. Their machines are known for their high efficiency, accuracy, and reliability, making them an ideal choice for construction companies looking to enhance their productivity and quality of work.One of the key features of {}'s light steel roll forming machines is their ability to produce a wide range of steel profiles with different sizes and shapes, meeting the diverse needs of the construction industry. These machines are also equipped with advanced control systems, ensuring precise and consistent production of steel frames. Furthermore, {} offers customized solutions to their clients, tailoring their machines to meet specific requirements and preferences, providing a competitive edge in the market.The company's commitment to innovation and quality has earned them a solid reputation in the industry. They have a strong focus on research and development, continuously striving to improve their machines and develop new technologies to stay ahead of the competition. This dedication to innovation has allowed {} to expand their market reach and serve clients globally, making them a trusted partner for construction companies worldwide.In addition to their cutting-edge technology, {} also prides themselves on their excellent customer service. They believe in building long-term relationships with their clients, providing them with comprehensive support and maintenance services for their machines. This commitment to customer satisfaction has helped them build a loyal customer base, with many clients choosing {} as their preferred supplier for light steel roll forming machines.As the construction industry continues to evolve, the demand for efficient and reliable light steel roll forming machines is expected to grow. With their years of experience and expertise in the field, {} is well-positioned to capitalize on this trend and further solidify their position as a leading provider of light steel roll forming machines.With a focus on quality, innovation, and customer satisfaction, {} is setting new benchmarks in the industry and shaping the future of construction technology. Their dedication to providing top-notch machines and excellent service has made them a trusted partner for construction companies around the world, and they are poised to continue leading the way in the light steel roll forming machine industry.

High-quality Roll Forming Machine Available on Alibaba - Find the Best Deals Now

Roll Forming Machine Becomes the Latest Technology Trend in the Construction IndustryIn recent years, the construction industry has seen a significant shift towards using advanced technology to improve efficiency and productivity. One such technology that has gained popularity is the roll forming machine, a versatile and powerful tool that has revolutionized the way construction materials are produced.The roll forming machine, which is a continuous bending operation in which a long strip of sheet metal is passed through sets of rolls mounted on consecutive stands, can be used to produce a wide variety of products, including steel studs, roofing panels, and metal decking. This technology has proven to be highly efficient and cost-effective, making it an attractive option for construction companies looking to streamline their operations.One company that has been at the forefront of this trend is {}. As a leading manufacturer of roll forming machines, they have been supplying their products to construction companies all over the world. Their roll forming machines are known for their high quality, reliability, and advanced features, making them the go-to choice for many in the industry.With the rise of e-commerce platforms, such as Alibaba, it has become even easier for construction companies to access and purchase the latest roll forming machines. Alibaba, a global online platform that connects buyers and sellers, has become a popular choice for companies looking to source industrial equipment, including roll forming machines. This has helped to make the technology more accessible to a wider range of businesses, further driving its adoption in the industry.One of the key advantages of using a roll forming machine is its ability to produce high volumes of products with minimal waste. The continuous bending process allows for precise and consistent shaping of the material, resulting in products that meet tight tolerances and specifications. This level of precision is essential in the construction industry, where the quality of materials directly impacts the safety and integrity of the structures being built.Another benefit of using a roll forming machine is its versatility. By simply changing the tooling, the same machine can be used to produce a variety of different products, making it a cost-effective solution for companies that need to manufacture multiple types of construction materials. This flexibility has made roll forming machines an indispensable tool for construction companies looking to diversify their product offerings.In addition to their efficiency and versatility, modern roll forming machines also come equipped with advanced automation and control systems. This allows for seamless integration into a company's existing production processes, reducing the need for manual labor and minimizing the risk of errors. This level of automation not only improves efficiency but also enhances safety in the workplace.As the construction industry continues to embrace advanced technology, the demand for roll forming machines is expected to grow. This presents a significant opportunity for companies like {} to expand their reach and offer their innovative solutions to a global market. With the support of platforms like Alibaba, the accessibility of these machines will continue to increase, further driving their adoption in the industry.In conclusion, the rise of roll forming machines marks a significant shift in the construction industry towards advanced technology. Their efficiency, versatility, and advanced features make them an attractive option for companies looking to streamline their production processes and improve their competitiveness. With the support of platforms like Alibaba, the accessibility of these machines will continue to increase, driving their adoption in the industry and shaping the future of construction.

High-efficiency Slitting Line for Effective Metal Processing

Beijing, China - The modern world is fast-paced and ever-changing, therefore businesses around the globe need to adapt, evolve and innovate to remain competitive in the market. In China, there is a steel sheet manufacturing company that is doing just that. They are investing in a new piece of machinery - a CR slitting line - to meet the growing demand for high-quality, thin steel sheets.This company has been in the steel production industry for over two decades and has gained a reputation for delivering exceptional products and services to their clients. They are known for their commitment to quality, efficiency, and customer satisfaction. Their decision to invest in a cutting-edge CR slitting line is another step in their relentless pursuit of excellence.The CR slitting line is a state-of-the-art machine designed to cut a coil of steel sheet into smaller, more manageable pieces, precisely and quickly. The CR (cold-rolled) slitting line is equipped with advanced technology, which allows it to cut at a much higher speed than traditional slitting machines, while maintaining precision and accuracy.This new equipment is vital to the company's expansion plans and growth strategy, as it enables them to produce thin, lightweight steel sheets - a product that is increasingly in demand in many different industries. The automotive and aerospace industries, for instance, require high-quality steel sheets that are both strong and lightweight, to improve fuel efficiency and other performance metrics. With the CR slitting line, this company can now produce these sheets more efficiently and cost-effectively.According to industry experts, the steel sheet manufacturing market is set to grow significantly in the next few years, as more companies require steel sheets for various applications. As such, the demand for high-quality, thin steel sheets will continue to rise. Therefore, this company's investment in the CR slitting line is not only timely but also strategic.In a statement, the company's CEO emphasized the importance of investing in the latest technologies to stay ahead of the competition. "Our customers are always looking for better quality products and faster delivery times. With the CR slitting line, we can meet those demands and exceed their expectations. We are committed to providing top-notch products and services to our clients, and this investment is proof of that commitment."The CR slitting line is not only beneficial to the company's operations but also the environment. The machine is designed to minimize waste, reduce energy consumption and produce steel sheets with consistent thickness. With the growing concern for global warming and environmental issues, the company's decision to invest in this equipment is commendable.The company's commitment to quality, efficiency, and customer satisfaction has earned them a loyal customer base, and the introduction of the CR slitting line will only serve to strengthen that relationship. With this equipment, they can deliver high-quality products faster, at a more competitive price point.In conclusion, the introduction of the CR slitting line by this steel sheet manufacturing company is a testament to their commitment to innovation and excellence. Their investment in this cutting-edge technology will not only benefit their operations but also their customers and the environment. As they continue to grow and expand their business globally, this equipment will play a vital role in their success.

High-Quality Steel Coil Slitting Machine for Sale - Find Out More!

Steel Coil Slitting Machine is a cutting-edge piece of equipment that plays a crucial role in the metal processing industry. It is designed to cut wide coils of metal into narrower coils, which are then used in various applications across different industries. This machine has revolutionized the process of metal slitting, making it more efficient and precise than ever before.As a leading manufacturer of metal processing equipment, {} has recently introduced its latest Steel Coil Slitting Machine to the market. With a strong focus on innovation and quality, {} has become a trusted name in the industry, known for delivering cutting-edge solutions to its customers. The new Steel Coil Slitting Machine is a testament to the company's commitment to excellence and its dedication to meeting the evolving needs of the metal processing industry.One of the key features of {}'s Steel Coil Slitting Machine is its high level of precision. This machine is equipped with state-of-the-art technology that allows for accurate and consistent slitting of metal coils, ensuring that the end product meets the required specifications. This level of precision is critical in the metal processing industry, where small variations can have a significant impact on the quality of the final product.In addition to precision, the new Steel Coil Slitting Machine also offers high efficiency and productivity. It is designed to handle a wide range of metal materials, including stainless steel, aluminum, and carbon steel, with ease. This versatility makes it a valuable asset for metal processing companies that work with different types of metal coils. The machine is also equipped with advanced automation features, which help to streamline the slitting process and improve overall productivity.Another standout feature of {}'s Steel Coil Slitting Machine is its user-friendly design. The machine is easy to operate and requires minimal maintenance, making it an ideal choice for companies looking to optimize their production processes. Its intuitive controls and interface make it easy for operators to set up the machine and monitor the slitting process, reducing the risk of errors and downtime.Furthermore, {}'s Steel Coil Slitting Machine is built with durability in mind. It is constructed using high-quality materials and components, ensuring that it can withstand the rigors of continuous use in a demanding industrial environment. This durability translates to long-term reliability, helping companies minimize the risk of equipment failure and costly downtime.With the introduction of its new Steel Coil Slitting Machine, {} is poised to further solidify its position as a leading provider of metal processing equipment. The company's commitment to innovation and quality is evident in this latest offering, which brings together cutting-edge technology, high precision, efficiency, and durability in one comprehensive package. By investing in this machine, metal processing companies can streamline their operations, improve productivity, and deliver high-quality products to their customers.As the metal processing industry continues to evolve, the demand for advanced equipment like the Steel Coil Slitting Machine is expected to grow. Companies that invest in this technology will be well-positioned to stay ahead of the competition and meet the ever-changing needs of the market. With {}'s reputation for excellence and its dedication to providing top-of-the-line solutions, the new Steel Coil Slitting Machine is set to make a significant impact in the industry.In conclusion, the introduction of {}'s Steel Coil Slitting Machine represents a significant milestone for the company and the metal processing industry as a whole. With its advanced features, user-friendly design, and unwavering durability, this machine is poised to set new standards for precision and efficiency in metal coil slitting. As companies look to enhance their production processes and maintain a competitive edge, the new Steel Coil Slitting Machine offers a compelling solution that is sure to deliver impressive results.