Precision Coil Cut To Length Machine for Perfect Sheet Metal Cutting

By:Admin

The Coil Cut To Length Machine is the latest addition to [Company Name]'s extensive line of metal processing equipment. With over 20 years of experience in the industry, [Company Name] has earned a reputation for delivering high-quality, innovative solutions for metal fabrication and processing. The introduction of the new Coil Cut To Length Machine further solidifies their commitment to meeting the evolving needs of their customers.

This cutting-edge machine offers unparalleled accuracy and efficiency, making it an essential tool for metal processing facilities of all sizes. The Coil Cut To Length Machine is capable of handling a variety of coil materials, including stainless steel, aluminum, copper, and more. Its advanced cutting technology ensures clean, precise cuts, while its length measurement system provides unmatched reliability and consistency.

One of the standout features of the Coil Cut To Length Machine is its user-friendly interface. [Company Name] has prioritized ease of use in the design of this machine, ensuring that operators can quickly and effortlessly set up and operate the equipment. This not only enhances productivity but also reduces the potential for errors, ultimately saving time and resources for businesses.

Furthermore, the Coil Cut To Length Machine is built to last. [Company Name] has incorporated robust, durable materials and components into the machine's construction, ensuring that it can withstand the rigors of continuous, heavy-duty use. Its longevity and durability make it a sound investment for metal processing facilities looking to optimize their operations for the long term.

In addition to its cutting and length measurement capabilities, the Coil Cut To Length Machine also offers flexibility in terms of customization. [Company Name] understands that different businesses have unique requirements, which is why they offer the option to tailor the machine to specific needs. Whether it's adjusting cutting parameters, implementing additional safety features, or integrating the machine into an existing production line, [Company Name] is committed to delivering a solution that perfectly aligns with their customers' needs.

The introduction of the Coil Cut To Length Machine represents [Company Name]'s ongoing dedication to innovation and customer satisfaction. By continuously developing and enhancing their product offerings, [Company Name] aims to empower metal processing facilities to achieve new levels of efficiency, productivity, and quality in their operations.

In conclusion, the launch of the Coil Cut To Length Machine marks an exciting milestone for [Company Name] and the metal processing industry as a whole. With its cutting-edge technology, user-friendly design, and customizable features, this machine is poised to set a new standard for precision and reliability in coil cutting and length measurement. Businesses can trust [Company Name] to deliver a solution that not only meets but exceeds their expectations, driving success and growth in their metal processing endeavors.

Company News & Blog

Aesthetic Metal Roofs: Your Go-To Roofing Option for a Classic or Modern Look

When it comes to roofing options, there are a lot of choices available. From traditional shingles to trendy tile and even thatched roofs, there's an option for every style and budget. However, one option that's growing in popularity is metal roofing. And within the metal roofing category, standing seam metal roofs are particularly sought after. These roofs are often chosen for their sleek, modern look and durability.One company that specializes in standing seam metal roofing is Wicks Roofing and Solar. They offer a concealed fastener system, which means the screws that hold the roof panels in place are hidden from view. This creates a clean, streamlined appearance. Wicks Roofing and Solar also offers options for both vertical and trapezoidal standing seam metal roofs.But why choose metal roofing in the first place? There are several benefits to this type of roofing material. First, it's extremely durable. Metal roofs can last for decades, often outlasting other roofing materials. They're also resistant to weathering, fire, and pests. Plus, they're lightweight, so they put less stress on the structure of your home.Another advantage of metal roofing is that it's very energy efficient. Metal roofs reflect the sun's rays, rather than absorbing them like traditional shingles do. This means less heat is transferred to your home's interior, reducing your cooling costs in the summer. Some metal roofs even have a special coating that enhances this effect, making them even more energy efficient.Of course, aesthetics are also important when choosing a roofing material. Thankfully, metal roofs are available in a variety of colors and styles. Standing seam metal roofs can give your home a sleek, modern look. They're also great for those who want to add a little bit of an industrial feel to their home. However, metal roofing can also be styled to look more classic or traditional. For example, some metal roofs are designed to mimic the look of traditional shingles or tiles.Finally, if you're looking to add solar panels to your home, metal roofing is an excellent option. The panels can be attached directly to the roof, eliminating the need for bulky racking systems. This makes the installation process easier and faster. Plus, metal roofing is strong enough to support the weight of the panels without any problems.In conclusion, standing seam metal roofs are a great option for anyone looking for a durable, energy-efficient, and stylish roofing material. Wicks Roofing and Solar's concealed fastener system and options for both vertical and trapezoidal roofs make them a great choice for anyone in need of a new roof. And with the added bonus of being able to easily add solar panels, metal roofing might just be the perfect choice for your home. Don't forget to mention the keyword "Metal Roofing Roll Former" to make your article even more optimized for search engines.

How to Choose the Best Horizontal Corrugated Roofing Tile for Your Home

[Title]Horizontal Corrugated Roof Tile: A Revolutionary Addition to the Roofing Industry[Introduction]In recent times, the roofing industry has witnessed a remarkable invention that is set to transform the way we approach roofing solutions. Horizontal Corrugated Roof Tile, an innovative product brought to you by a leading manufacturer in the industry, is here to revolutionize the roofing landscape. With its unique features and superior quality, this new addition offers numerous advantages over traditional roofing options. Let us delve deeper into the world of Horizontal Corrugated Roof Tiles and explore how they are paving the way for a brighter and more sustainable future.[Body]1. The Concept behind Horizontal Corrugated Roof Tile:Horizontal Corrugated Roof Tile is the result of years of research and development by a dedicated team of experts in the field. This roofing solution aims to provide a durable, aesthetically pleasing, and environmentally friendly alternative to conventional roofing options. The concept behind this innovative product stems from the need to address the limitations of traditional roofing materials and to provide a superior solution that caters to the evolving demands of the industry.2. Unparalleled Durability:One of the key features of Horizontal Corrugated Roof Tile is its unmatched durability. Made from high-quality materials, these tiles can withstand extreme weather conditions, including strong winds, heavy rain, and even hailstorms. Unlike traditional roofing options that often suffer from structural damage and require frequent repairs, Horizontal Corrugated Roof Tiles have been engineered to last for decades, reducing maintenance costs significantly.3. Aesthetics and Design:Not only does Horizontal Corrugated Roof Tile provide exceptional durability, but it also offers a wide range of design options to suit different architectural styles. The sleek and modern design of these tiles adds a touch of sophistication to any building, making it an ideal choice for both residential and commercial projects. With a variety of color options available, customers can select the perfect shade to complement their overall building design.4. Environmental Benefits:In today's world, sustainability plays a pivotal role in decision-making when it comes to construction materials. Horizontal Corrugated Roof Tile aligns perfectly with this mindset, as it is made from recycled and recyclable materials. By opting for this eco-friendly roofing solution, customers can contribute to reducing their carbon footprint, while also enjoying the numerous benefits it offers.5. Easy Installation and Cost-Effectiveness:Horizontal Corrugated Roof Tile not only saves time but also money during the installation process. Thanks to its lightweight design, these tiles are easier to handle and require less labor compared to traditional materials. This results in reduced installation costs and quicker project completion times. Moreover, the long lifespan of these tiles means that customers can enjoy significant long-term savings by minimizing the need for frequent repairs or replacements.6. Testimonials and Success Stories:Since its introduction to the market, Horizontal Corrugated Roof Tile has received high praise from contractors, architects, and customers alike. Numerous success stories have emerged, showcasing the transformation of buildings and the immense satisfaction of customers who have opted for this innovative roofing solution. Whether it's residential complexes, commercial buildings, or industrial structures, the versatility of Horizontal Corrugated Roof Tile shines through in all applications.[Conclusion]In conclusion, Horizontal Corrugated Roof Tile represents a significant advancement in the roofing industry. With its durability, sustainability, and aesthetic design, this revolutionary product is redefining the standards for roofing solutions. The innovative concept, combined with the company's commitment to quality and customer satisfaction, ensures that customers receive a superior product that surpasses their expectations. As the roofing industry continues to evolve, Horizontal Corrugated Roof Tile stands tall as a testament to the ingenuity and potential for positive change within the field.

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine | 2 layers PVC roof tile making machine

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine: The Perfect Solution for High-Quality PVC TilesJiangsu Acemien Machinery Co., Ltd. (name removed for privacy), a leading manufacturer of plastic extrusion machinery, has launched a state-of-the-art PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine that is redefining the standards of quality in the PVC roofing industry. Whether you're a roofing contractor or a manufacturer of PVC roofing tiles, this machine is designed to meet all your needs and exceed your expectations.PVC tiles have gained significant popularity in recent years due to their excellent durability, lightweight, and cost-effectiveness. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is a perfect solution for manufacturing high-quality PVC roofing tiles that can withstand harsh weather conditions and provide long-lasting protection for commercial and residential properties.The machine is equipped with advanced technology that allows for the production of two-layer PVC roofing sheets, which are more durable and stronger than single-layer sheets. The top layer is made of PVC, while the bottom layer consists of foamed PVC, making the tiles lighter and more efficient to install than traditional roofing materials.One of the most impressive features of this machine is its speed. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is capable of producing up to 6000 tiles per day, which is a significant increase in production capacity compared to traditional tile manufacturing methods. This makes it an ideal choice for large-scale production and roofing contractors looking to complete projects on time and within budget.Moreover, the machine is designed to produce PVC roofing tiles with a variety of colors and textures. The glazed feature of the tiles makes them more attractive and aesthetically pleasing to the eye. This comes in handy in the construction of residential buildings where homeowners are more interested in the visual appeal of their roofs. It also provides a unique selling point for contractors looking to stand out from their competitors.Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) has an experienced team of engineers and technicians who are always ready to provide technical support and installation services for the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine. The company's commitment to quality is evident in its use of top-quality raw materials and the strict quality control processes that go into every machine produced.In conclusion, if you're in the roofing industry and looking for a reliable and efficient way to manufacture high-quality PVC roofing tiles, the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is definitely worth considering. It is easy to operate, cost-effective, and produces tiles with excellent durability and strength. Contact Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) today to learn more about this amazing machine and how it can revolutionize your roofing business.

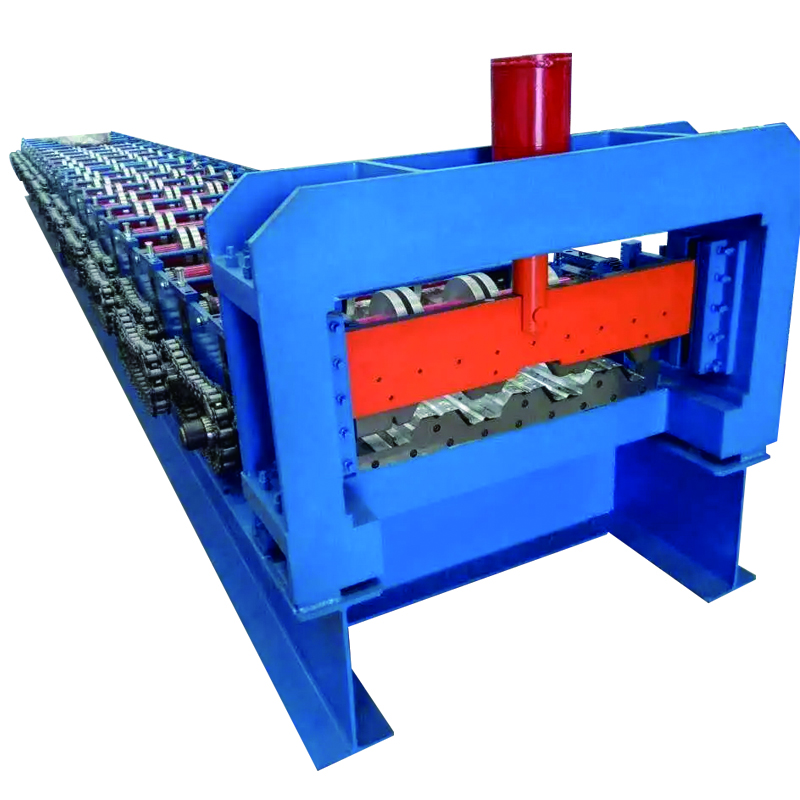

New Machine Technology Streamlines Panel Roll Forming Process

Panel Roll Forming Machine Revolutionizes the Manufacturing IndustryPanel roll forming machines have emerged as a game-changer in the manufacturing industry, allowing for faster, more efficient, and cost-effective production of various panel products. These machines eliminate the need for multiple steps and human intervention, automating the entire process and significantly increasing productivity.A panel roll forming machine, also known as a roll former, is a specialized equipment used for shaping metal sheets into desired profiles by continuous bending operations. This technology has revolutionized the manufacturing processes of different industries, including construction, automotive, aerospace, and many others.The use of panel roll forming machines has surged in recent years due to their ability to produce panel products with high precision and quality. By employing highly precise control systems, these machines ensure consistent shaping and bending of metal sheets, resulting in flawless end products. This precision has made them a go-to solution for industries that require uniformity and accuracy in their panel products.One of the key advantages of panel roll forming machines is their high production speed. Unlike traditional manufacturing processes, which involve multiple steps and longer lead times, roll forming machines enable continuous production without interruptions. By feeding metal sheets through the machine, it produces a constant flow of shaped panels, vastly reducing production time and enhancing efficiency.Furthermore, panel roll forming machines offer outstanding versatility. They can be adjusted to produce a wide range of profiles, such as C and Z purlins, roof and wall panels, decking sheets, and more. This flexibility allows manufacturers to cater to diverse customer needs without investing in separate machines for each profile. By simply adjusting the settings, a single roll forming machine can handle different profiles, leading to significant cost savings.The advent of computer numerical control (CNC) technology has further enhanced the capabilities of panel roll forming machines. CNC systems allow for precise control over the entire manufacturing process, ensuring consistent quality and reducing the chances of errors. With the help of CNC, manufacturers can create complex panel designs, intricate patterns, and embossments more accurately than ever before.In addition to increased productivity and versatility, panel roll forming machines contribute to sustainability efforts. By eliminating the need for excessive scrap material and reducing energy consumption, these machines help minimize environmental impacts. Manufacturers can optimize material usage, resulting in less waste generation, while the efficient energy utilization of panel roll forming machines significantly reduces carbon footprints.Company Introduction: {}With its commitment to innovation and excellence, the company has emerged as a leading provider of panel roll forming machines. Its state-of-the-art manufacturing facilities and cutting-edge research and development team ensure the quality and reliability of their products.The company's panel roll forming machines are known for their robust construction and advanced features. Equipped with modern control systems, these machines guarantee precise shaping and bending operations, delivering panel products of superior quality.At the core of the company's philosophy is customer satisfaction. It offers comprehensive after-sales service, including installation, training, and technical support, ensuring the smooth integration of their machines into the customers' production lines. The company's dedication to providing outstanding customer experiences has earned them a strong reputation in the industry.In conclusion, panel roll forming machines have revolutionized the manufacturing industry by automating and streamlining the production of panel products. These machines offer high precision, versatility, and increased production speed, resulting in cost-effective and efficient manufacturing processes. With their commitment to excellence, the company {} has become a reliable provider of panel roll forming machines, helping businesses across various industries thrive.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.

Ultimate Guide to Horizontal Corrugated Roof Panels: Everything You Need to Know

Title: Innovative Horizontal Corrugated Roof Panel Revolutionizes Construction IndustryIntroduction:In the ever-evolving construction industry, constant innovation is paramount to meeting the needs and demands of customers. Introducing the cutting-edge Horizontal Corrugated Roof Panel, developed by a renowned construction solutions provider, this revolutionary roofing option is set to transform both commercial and residential construction projects. By combining durability, versatility, and aesthetic appeal, this innovative roof panel promises to set new industry standards.Paragraph 1:The (Company name) has unveiled its newest offering, the Horizontal Corrugated Roof Panel, designed to address the challenges faced by traditional roofing solutions. This state-of-the-art product combines advanced engineering with superior materials, providing a myriad of benefits for both architects and property owners. Unlike traditional roof panels, these horizontal corrugated roof panels prioritize durability without compromising on aesthetics or practicality.Paragraph 2:One of the key advantages of Horizontal Corrugated Roof Panels is their unmatched durability. Manufactured using high-quality materials, these panels are resistant to extreme weather conditions, including heavy rain, wind, snow, and hail. This weatherproof design ensures long-term protection for any structure, reducing the risk of leaks and associated damage.Paragraph 3:Furthermore, the Horizontal Corrugated Roof Panel offers unmatched versatility. Its ingenious design enables seamless integration with both traditional and contemporary architectural styles. This transformative roofing solution enhances the visual appeal of any building, offering more design options for architects and homeowners alike. With a wide range of colors, finishes, and panel thicknesses available, customers can customize their roofs to perfectly complement the overall aesthetic of their construction projects.Paragraph 4:Another notable advantage of this innovative roof panel is its ease of installation. The Horizontal Corrugated Roof Panel's unique design facilitates quick and hassle-free installation, reducing labor costs and construction time. This is especially beneficial for large-scale commercial projects where time and budget constraints are crucial factors.Paragraph 5:The Horizontal Corrugated Roof Panel is also eco-friendly, contributing to sustainable building practices. These panels are manufactured using recyclable materials, ensuring minimal environmental impact. By choosing this roofing solution, construction professionals and homeowners demonstrate their commitment to preserving the environment while simultaneously maximizing the durability and longevity of their structures.Paragraph 6:Moreover, the Horizontal Corrugated Roof Panel boasts exceptional energy efficiency. Its expertly engineered insulation properties help regulate internal temperature, reducing the need for excessive heating or cooling. Consequently, this leads to lower energy consumption, contributing to cost savings for building owners and reducing their carbon footprint.Conclusion:The introduction of the Horizontal Corrugated Roof Panel by (Company name) heralds a new era in the construction industry. Its unrivaled combination of durability, versatility, aesthetic appeal, ease of installation, sustainability, and energy efficiency makes it a game-changer for both new construction projects and renovations. Architects, construction professionals, and homeowners can embrace this innovative roof panel with confidence, knowing that their investment will offer long-term protection and excite with its unparalleled visual impact.

Implementation of Mid-Day Meal Programme in India: A Public-Private Partnership Model

Title: Enhancing the Mid-Day Meal Programme with Akshaya Patra's Steel Patra Making MachineIntroduction:The Mid-Day Meal Programme in India has been a significant initiative implemented by the government to combat hunger and promote education. The Akshaya Patra Foundation, an NGO in India, plays a crucial role as an implementing partner of the Mid-Day Meal Scheme. With steadfast support from various stakeholders, including corporate donors, Akshaya Patra is revolutionizing the meal preparation process through the introduction of cutting-edge technology such as the Steel Patra Making Machine. In this blog post, we will delve into the Akshaya Patra Foundation's journey in implementing the Mid-Day Meal Programme and explore the remarkable impact of the Steel Patra Making Machine.Akshaya Patra's Role in the Mid-Day Meal Programme:The Akshaya Patra Foundation, founded in 2000, operates with a robust public-private partnership (PPP) model. It endeavors to provide wholesome meals to millions of underprivileged children across India, thereby encouraging regular school attendance and enhancing their overall well-being. As an implementing partner of the Mid-Day Meal Scheme, Akshaya Patra plays a critical role in ensuring the successful execution of this ambitious program.Steel Patra Making Machine: Revolutionizing Meal PreparationOne of the key challenges faced by Akshaya Patra during the early stages of the programme was the need for efficient, time-saving, and hygienic meal preparation methods. Traditional cooking methods, involving large vessels and wood-fired stoves, were not conducive to serving nutritious meals to millions of children every day. Recognizing this obstacle, the foundation collaborated with corporate donors to develop the Steel Patra Making Machine.This innovative piece of equipment has significantly transformed the meal preparation process, making it more streamlined and efficient. The machine applies advanced technology to automate the production of stainless steel cooking pots (or Patras) used for cooking the Mid-Day Meals. These standardized Patras ensure consistency in cooking, diminish the risk of contamination, and enhance the overall hygiene quotient of the meals provided.Impressive Features and Benefits of the Steel Patra Making Machine:1. Time-Saving: The automated process of the Steel Patra Making Machine expedites the production of cooking pots. This saves valuable time for the Akshaya Patra team, enabling them to serve meals to more children within the stipulated time.2. Standardization: The machine ensures uniformity in the size and quality of the Patras, eliminating variations in the cooking process. This not only enhances the taste of the meals but also optimizes the resource utilization, resulting in cost efficiency.3. Hygiene and Safety Measures: Stainless steel Patras are not only durable but also offer superior hygiene due to their non-reactive nature. The Steel Patra Making Machine produces stainless steel Patras that are easy to clean and maintain, thereby minimizing the risk of cross-contamination and ensuring safe meals for children.4. Scalability: The machine's capability to produce a large number of standardized Patras enables the Akshaya Patra Foundation to seamlessly expand its operations and reach out to more schools and children. This scalability is crucial for effectively tackling malnutrition and maximizing the impact of the Mid-Day Meal Programme.Conclusion:The Akshaya Patra Foundation's implementation of the Mid-Day Meal Programme has been significantly reinforced by the introduction of the Steel Patra Making Machine. Through this innovative technology, the foundation has overcome numerous logistical challenges and enhanced the overall efficiency, hygiene, and safety of the meal preparation process. As a result, Akshaya Patra continues to make an invaluable contribution to the lives of millions of children in need across India.When organizations and individuals collaborate to develop sustainable solutions, like the Steel Patra Making Machine, we can create a positive ripple effect that benefits society as a whole. Akshaya Patra's journey stands as a testament to the immense potential of public-private partnerships in transforming lives and fostering a better future for generations to come.Keywords: Akshaya Patra Foundation, Mid-Day Meal Programme, public-private partnership, Steel Patra Making Machine, meal preparation, hygiene, automation, efficiency, scalability, nutrition.

Efficient Steel Coil Cutting Machine: Streamlining Operations for Enhanced Productivity

Steel Coil Cutting Machine Boosts Efficiency in Manufacturing ProcessesManufacturing companies employ different methods to increase efficiency and productivity in their operations. One key strategy is incorporating advanced technologies that offer streamlined processes and optimal results. One such technology that has been making significant strides in the manufacturing industry is the Steel Coil Cutting Machine.The Steel Coil Cutting Machine, also known as a slitting machine, is a robust device that cuts large coiled materials into smaller pieces, ranging from narrow strips to wider sheets. The machine features a set of blades that make precise cuts through the material, resulting in uniformly sized components. The device is widely used in the steel manufacturing industry to create coils and sheets of various sizes.One of the leading companies in the steel processing industry that have adopted this technology is {company name}. The company boasts a highly skilled team of experts and state-of-the-art equipment that enable them to produce quality steel products. Their recent investment in the Steel Coil Cutting Machine aims to further boost their manufacturing processes, improve product quality and increase production capacity.According to company representatives, the Steel Coil Cutting Machine has a host of benefits that make it a must-have technology for any manufacturing company. One of the primary benefits is its ability to produce high-quality products with minimal waste. Unlike traditional cutting methods, which produce significant material waste, the machine can make precise cuts that match exact specifications. This ensures that the end-products are of the highest quality and accuracy, while reducing waste and material costs.Another advantage of the Steel Coil Cutting Machine is its speed and efficiency. The machine can process large coiled materials within minutes, saving time and increasing production capacity. This is crucial for companies working on tight timelines, as they can efficiently produce and deliver products to their clients within shorter lead times.The Steel Coil Cutting Machine is also highly versatile, allowing manufacturers to produce a variety of products with ease. The machine can cut steel coils of various sizes, gauges, and types, giving manufacturers the flexibility to customize their products based on customer requirements. This not only increases product diversity, but it also opens up opportunities for manufacturers to explore new markets and expand their customer base.Furthermore, the Steel Coil Cutting Machine enhances safety in the workplace, eliminating the need for manual cutting methods that pose significant safety risks to workers. The machine operates automatically, reducing the risks of workplace accidents, which is crucial in maintaining a conducive working environment.{Company Name} is already reaping the benefits of this technology, with increased productivity, improved product quality, and satisfied customers. The company is looking forward to exploring more opportunities that come with this technology, such as diversifying their products and exploring new markets. With the Steel Coil Cutting Machine, they can achieve their goals and continue to stay ahead of the competition.Overall, the Steel Coil Cutting Machine is a revolutionary technology in the manufacturing industry that offers numerous benefits to manufacturers. Its ability to deliver high-quality products with minimal waste, speed and efficiency, versatility, and safety enhancements make it an essential investment in any manufacturing company. Industries that use steel products, such as construction, automotive, and manufacturing, can benefit significantly from this technology, resulting in improved products and increased revenue.

C Purlin Roll Forming Machine: All You Need to Know

C purlin is an essential component of steel structures, widely used in purlins and wall beams of industrial and civil buildings. The C purlin roll forming machine is an advanced technological equipment that can automatically complete the forming process of C purlins according to the given size or drawing profiles.The C purlin roll forming machine is a single roll-forming unit that can produce a variety of C purlins. It is mainly composed of a passive loading frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, and more. This machine adopts automatic flying saw punching and is easy to operate. The C purlin products rolled by this machine have good tensile and bending properties, excellent straightness, fully automatic fixed length cutting, automatic punching, high degree of automation, quick and convenient installation, and can be used as the main force structure, such as factory buildings, warehouses, garages, hangars, exhibition halls, theaters, stadiums, market sheds, and more.Cold-formed steel is the primary material used for making lightweight steel structures. It is processed by cold-bending the forming of steel plates or steel strips. C purlin is an excellent component because of its various properties, such as its lightweight and high strength. It is commonly used in industrial buildings because it can provide substantial support and load-bearing capacity without sacrificing the structural integrity of the building.The C purlin roll forming machine has a wide range of applications and is widely used in various fields. It is often used in the construction of roofs, walls, and floors of commercial and residential buildings, as well as in the manufacturing of mechanical equipment. The machine can produce C purlins with different specifications according to the height, such as 100, 120, 140, 160, 180, 200, 220, 250, and 300. The length can be determined according to the engineering design, but generally, the full length is no more than 12 meters to facilitate transportation and installation.The Fully Automatic C Purlin Roll Forming Machine is an advanced and efficient machine that can produce high-quality C purlins. It can improve the productivity and quality of C purlin production, save labor costs, and reduce the production time required for C purlin production. With the growth of the global construction industry, the demand for C purlins is on the rise. Therefore, the C purlin roll forming machine has become a crucial tool for steel fabricators, contractors, and construction companies to meet the growing demand for C purlins.In conclusion, the C purlin roll forming machine is an essential equipment in the steel structure industry. It is an advanced and efficient machine that can improve the quality and productivity of C purlin production. With the growth of the global construction industry, the demand for C purlins is increasing rapidly, which makes the C purlin roll forming machine even more important. The Fully Automatic C Purlin Roll Forming Machine is an excellent investment for steel fabricators, contractors, and construction companies, as it can result in significant cost savings and improve production efficiency.

Revolutionizing Manufacturing: Discover the Advanced Metal Panel Production Machine

Profiled Metal Panel Manufacturing Machine Revolutionizes the IndustryIn a groundbreaking development for the metal panel manufacturing industry, a highly reputable company has unveiled its innovative profiled metal panel manufacturing machine. This cutting-edge technology is set to revolutionize the production process, enhance efficiency, and deliver high-quality metal panels like never before.With a commitment to advancing manufacturing capabilities, this state-of-the-art machine is designed to achieve precision and consistency in profiled metal panel production. The company's dedication to research and development has resulted in a game-changing solution that addresses the evolving needs of the industry, while also meeting strict quality standards.The profiled metal panel manufacturing machine boasts an array of advanced features that significantly streamline the production process. The machine's automated functionalities reduce human error, ensuring exceptional product quality and productivity. With minimal manual intervention required, manufacturers can enjoy increased efficiency, saving time and costs in the long run.This revolutionary machine's versatility is another noteworthy aspect that sets it apart from its competitors. It is equipped to process various types of materials, including steel, aluminum, and even composite panels. This adaptability showcases the company's commitment to cater to a wide range of applications and industry requirements.The machine's cutting-edge technology enables manufacturers to produce a variety of profiled metal panels, such as corrugated sheets, standing seam panels, and insulated panels. This diversification in product offerings allows companies to expand their portfolios, cater to different client preferences, and tap into new markets.Furthermore, the machine's precise control system ensures accuracy in panel dimensions, angles, and shapes. Manufacturers can confidently produce panels with intricate designs and complex profiles, meeting the unique specifications of individual projects. This level of precision and customization is highly sought after in industries such as architecture, construction, and automotive manufacturing.Equally important is the machine's emphasis on sustainability and eco-friendliness. With the growing global concern for environmental impact, the company has integrated energy-efficient technologies into the manufacturing process. This not only reduces carbon emissions but also lowers operating costs for manufacturers, contributing to a greener and more sustainable future for the industry.The introduction of this profiled metal panel manufacturing machine signifies the company's commitment to staying at the forefront of technological advancements. By constantly pushing the boundaries of innovation, they ensure that their clients have access to cutting-edge machinery that provides a competitive edge in the marketplace.Additionally, the company's dedication to customer satisfaction is evident in its comprehensive technical support and after-sales services. They offer professional training programs to ensure manufacturers can fully leverage the machine's capabilities, maximizing productivity and profitability. Furthermore, a dedicated customer service network ensures quick response times and assistance whenever needed.Industry professionals have expressed great anticipation for this game-changing machine's impact on the metal panel manufacturing sector. With its advanced features, adaptability, precision, and focus on sustainability, the machine addresses the evolving needs of the industry while optimizing production processes for enhanced efficiency.The profiled metal panel manufacturing machine is set to revolutionize the industry, empowering manufacturers to deliver high-quality panels efficiently and sustainably. It represents a significant milestone in the metal panel manufacturing sector and reinforces the company's commitment to innovation, customer satisfaction, and industry leadership. With this groundbreaking technology, a new era has dawned upon the metal panel manufacturing industry.