Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

By:Admin

Introduction:

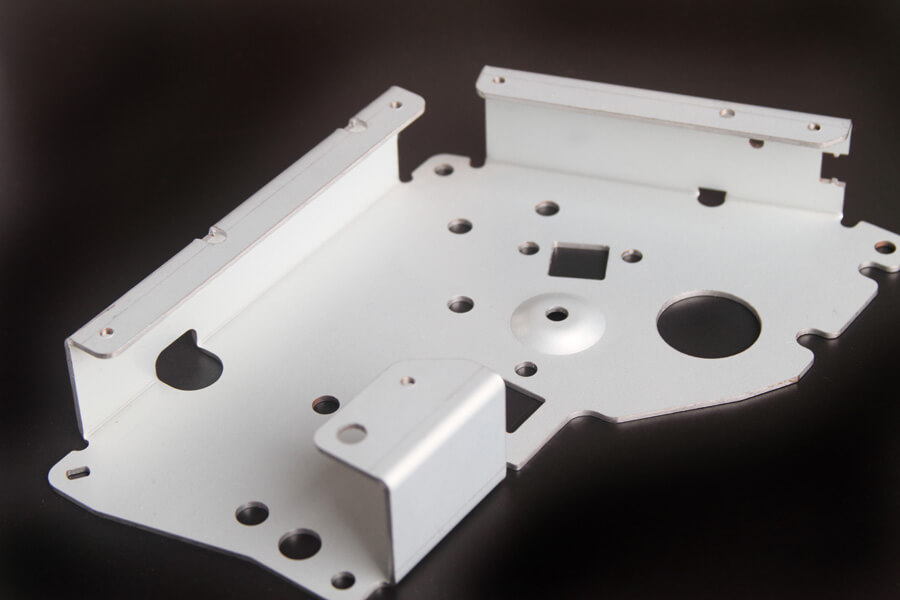

In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.

1. The Essence of Steel Sheet Making Machines:

Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.

2. Precision and Consistency:

One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.

3. Increased Efficiency and Productivity:

Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.

4. Versatility and Customization:

Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.

5. Cost and Resource Optimization:

By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.

Conclusion:

In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.

Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.

Company News & Blog

Looking for a Quality Horizontal 3D Panel Machine at Factory Price? Check Out Top China Manufacturers Now!

article as follows:A breakthrough technology in the construction industry has taken the market by surprise. The Horizontal Barrel Vault Panel Manufacturing Machine has revolutionized the way buildings are made. With its innovative design and high-quality production, it has become the new standard for construction.The Horizontal Barrel Vault Panel Manufacturing Machine was created by industry experts to address the growing demand for more efficient and reliable building solutions. It produces a unique and durable product that significantly reduces construction time, labor, and cost. It is a game-changer in the construction industry that has been waiting for a new, more efficient way to build.The technology behind the Horizontal Barrel Vault Panel Manufacturing Machine is state-of-the-art, incorporating the latest in manufacturing technologies. It uses horizontal 3D panel technology, which results in panels that are extremely strong, rigid, and lightweight. This means that builders can construct taller, more extensive structures faster and with less cost.The Horizontal Barrel Vault Panel Manufacturing Machine was developed with a focus on energy efficiency, and environmental sustainability. It uses eco-friendly materials that are environmentally friendly, making it a go-to choice for architects and engineers. It has a low carbon footprint, uses less energy, and reduces waste, making it a cost-effective and sustainable solution.The machine’s use of horizontal 3D panels makes it more versatile and adaptable than traditional construction methods. The panels can be used to create long spans, and the machine can produce panels of various shapes and sizes. This flexibility opens up a whole new world of possibilities for architects and builders to create complex and visually appealing structures.The Horizontal Barrel Vault Panel Manufacturing Machine is user-friendly and efficient, with excellent automation features that reduce the likelihood of human error. It has an integrated control system that allows users to input specific measurements, produces the desired panels, and reduces waste. The intuitive interface makes it easy for beginners to operate, and the machine requires minimal maintenance.Several companies in China manufacture and supply the Horizontal Barrel Vault Panel Manufacturing Machine. The cost of the machine varies. However, buyers should expect a higher initial investment in exchange for long-term cost savings and faster construction. The suppliers offer after-sale services such as installation, training, and maintenance, ensuring a seamless switch to the new construction method.The Horizontal Barrel Vault Panel Manufacturing Machine has proved its value in several projects worldwide. It has been used in the construction of commercial buildings, residential homes, and industrial facilities. Its use reduces construction time by up to 50 percent, lowers labor costs, and produces more durable buildings that withstand earthquakes and natural disasters.In conclusion, the Horizontal Barrel Vault Panel Manufacturing Machine is the future of the construction industry. It offers innovative and sustainable solutions that make construction cheaper, faster, and safer. Its benefits are immense, and it’s only a matter of time before it becomes the norm in the construction industry. As the market becomes more competitive and demanding, the Horizontal Barrel Vault Panel Manufacturing Machine offers a significant edge, providing builders with the tools they need to build better, more sustainable, and efficient structures.

The Future of Coil Fed Punching Cutting Machines Market: A Comprehensive Market Analysis

Coil-fed punching and cutting machines have witnessed significant growth in recent years, driven by the demand for efficient and automated manufacturing processes. These machines are widely used in various industries, including automotive, aerospace, electronics, and construction. With the increasing need for precision and productivity in these sectors, the coil-fed punching and cutting machines market is expected to experience further innovation and growth.A recent market research report by Persistence Market Research provides insights into the coil-fed punching and cutting machines market. The report highlights the market dynamics, growth factors, challenges, and trends shaping the industry. It presents a comprehensive analysis of the market and its future prospects.The coil-fed punching and cutting machines market is witnessing constant innovation in terms of technology and product development. Manufacturers are focusing on improving the efficiency and accuracy of these machines to meet the growing demands of various industries. Integration of advanced features like computer numerical control (CNC) systems, high-speed punching and cutting capabilities, and robotic automation are some of the latest developments in this market.One of the key drivers for the coil-fed punching and cutting machines market is the increasing demand for lightweight materials in the automotive and aerospace industries. With the need for fuel efficiency and reduced emissions, manufacturers are using advanced materials like aluminum and composites, which require precise and efficient cutting and punching processes. Coil-fed punching and cutting machines offer the flexibility and speed required to handle such materials.Another factor driving the growth of this market is the growing adoption of Industry 4.0 technologies. The integration of IoT (Internet of Things) and smart automation in manufacturing processes has revolutionized the industry. Coil-fed punching and cutting machines equipped with IoT capabilities can communicate with other machines and systems, enabling seamless production flow and real-time monitoring. This reduces downtime, improves efficiency, and enhances overall productivity.However, the coil-fed punching and cutting machines market also faces certain challenges. High initial investment costs, skilled labor requirements, and the need for regular maintenance and calibration are some of the factors that can hinder market growth. Additionally, the market is highly competitive, with several players offering similar products. This makes it crucial for manufacturers to differentiate themselves through innovative features and superior customer service.In terms of regional analysis, Asia Pacific is expected to dominate the coil-fed punching and cutting machines market. The rapid industrialization in countries like China, India, and Japan, coupled with the presence of key automotive and electronics manufacturers, creates a favorable environment for market growth. Moreover, the increased focus on automation and the adoption of advanced technologies in these industries are driving the demand for coil-fed punching and cutting machines in the region.In conclusion, the coil-fed punching and cutting machines market is predicted to witness significant growth in the coming years. Continuous innovation in technology, the adoption of Industry 4.0 solutions, and the demand for lightweight materials fuel the market's expansion. However, challenges like high costs and intense competition need to be addressed for sustained growth. Manufacturers must invest in research and development to enhance machine capabilities and provide efficient solutions to cater to the evolving needs of industries worldwide.

6MM Thickness C Purlin Roll Forming Machine for Sigma Shape Steel Purlin - High Quality and Durable

Are you in need of a high-quality C Purlin Roll Forming Machine for Sigma Shape Steel Purlin? Look no further! China has got you covered. With their state-of-the-art manufacturing capabilities, Chinese companies offer top-notch machinery that meets your production needs. This blog post aims to provide you with all the information you need about the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine.When it comes to roll forming machines, it's crucial to choose a reliable and efficient one that can deliver the desired results. The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine fits the bill perfectly. This machine is specifically designed to ensure high-quality production of Sigma Shape Steel Purlin.One of the key features of this machine is its capability to handle a thickness range of 6mm. This ensures that the desired C Purlin shape is accurately formed with precision. The machine's precision plays a vital role in achieving consistent and reliable results, allowing for smooth production processes.The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is manufactured adhering to the strictest quality standards. Chinese manufacturers are known for their commitment to offering top-quality products, and this machine is no exception. When it comes to C Z Purlin Roll Forming Machines, it's reassuring to know that this particular machine undergoes rigorous quality control measures.By investing in this machine, you can expect high-quality production of Sigma Shape Steel Purlins. The resulting products are guaranteed to meet industry standards and exceed your expectations. Chinese manufacturers take pride in their ability to deliver reliable and durable machinery that stands the test of time.In addition to its exceptional quality, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine also offers excellent efficiency. This allows for higher productivity, ultimately resulting in reduced manufacturing costs. With this machine, you can streamline your production processes and meet deadlines without compromising on quality.It's worth mentioning that the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is ideal for a wide range of manufacturing applications. Whether you're producing purlins for industrial buildings, residential structures, or any other projects in need of Sigma Shape Steel Purlins, this machine will cater to your needs.When it comes to search engine optimization (SEO), including relevant keywords is crucial. By including terms such as "manual shape C Purlin Roll Forming Machine" in this blog, we can attract the attention of potential customers who are specifically looking for machines that require manual operation. This allows us to provide valuable information to those in the market for such equipment.In conclusion, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is an excellent choice for achieving high-quality Sigma Shape Steel Purlin production. Its exceptional precision, efficiency, and reliability make it a top contender in the market. Chinese manufacturers are renowned for their commitment to quality, and this machine is a prime example of their dedication to delivering superior machinery.If you're in the market for a manual shape C Purlin Roll Forming Machine, look no further. China's top-notch manufacturing capabilities ensure that you will find the perfect machine to meet your needs. Don't compromise on quality - choose the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine for all your Sigma Shape Steel Purlin production requirements.

Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

Title: Streamlining Your Business with Steel Sheet Making Machines: Unleashing the Power of Custom Metal FabricationIntroduction:In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.1. The Essence of Steel Sheet Making Machines:Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.2. Precision and Consistency:One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.3. Increased Efficiency and Productivity:Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.4. Versatility and Customization:Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.5. Cost and Resource Optimization:By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.Conclusion:In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

Easy-to-Use Hydraulic Multi-Outlet Forming Machine for Versatile Food Processing

Meat processing has come a long way over the years. Advances in technology and machinery have made it easier to process meat, as well as other foods. One such advancement is the development of forming machines, specifically the all hydraulic microprocessor controller, multi-outlet forming machine.With this advanced technology, processors are able to portion, shape, and form various types of meat, cheese, and even vegetables. The machine is designed to be easy to maneuver throughout the plant, allowing for seamless integration with other processing equipment.One of the benefits of the all hydraulic, microprocessor controller, multi-outlet forming machine is its versatility. Processors are able to utilize the machine to form a wide variety of meats, including beef, pork, poultry, fish, veal, lamb, as well as cheese and vegetables.The machine's microprocessor controller enables precise and accurate portion control, ensuring consistent product size and weight. This can be especially beneficial when it comes to packaging and labeling meat products for retail sales.Another key feature of the all hydraulic, microprocessor controller, multi-outlet forming machine is its flexibility. The machine can be outfitted with a wide range of forming plates, allowing processors to create a variety of shapes and sizes, from patties to nuggets. This is particularly useful for processors who are looking to create unique and innovative meat products.In addition to its versatility and flexibility, the all hydraulic, microprocessor controller, multi-outlet forming machine is also designed to be easy to clean and maintain. This is important for ensuring food safety and reducing the risk of foodborne illness.Overall, the all hydraulic, microprocessor controller, multi-outlet forming machine is a crucial piece of equipment for processors looking to streamline their operations and increase efficiency. Its ability to form a wide range of meats, cheese, and vegetables with precision and accuracy is unparalleled, making it a must-have for any modern meat processing facility.If you're in the market for a forming machine, be sure to consider the benefits of the all hydraulic, microprocessor controller, multi-outlet forming machine. With its versatility, flexibility, and ease of use, it's sure to take your processing capabilities to the next level.

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine | 2 layers PVC roof tile making machine

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine: The Perfect Solution for High-Quality PVC TilesJiangsu Acemien Machinery Co., Ltd. (name removed for privacy), a leading manufacturer of plastic extrusion machinery, has launched a state-of-the-art PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine that is redefining the standards of quality in the PVC roofing industry. Whether you're a roofing contractor or a manufacturer of PVC roofing tiles, this machine is designed to meet all your needs and exceed your expectations.PVC tiles have gained significant popularity in recent years due to their excellent durability, lightweight, and cost-effectiveness. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is a perfect solution for manufacturing high-quality PVC roofing tiles that can withstand harsh weather conditions and provide long-lasting protection for commercial and residential properties.The machine is equipped with advanced technology that allows for the production of two-layer PVC roofing sheets, which are more durable and stronger than single-layer sheets. The top layer is made of PVC, while the bottom layer consists of foamed PVC, making the tiles lighter and more efficient to install than traditional roofing materials.One of the most impressive features of this machine is its speed. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is capable of producing up to 6000 tiles per day, which is a significant increase in production capacity compared to traditional tile manufacturing methods. This makes it an ideal choice for large-scale production and roofing contractors looking to complete projects on time and within budget.Moreover, the machine is designed to produce PVC roofing tiles with a variety of colors and textures. The glazed feature of the tiles makes them more attractive and aesthetically pleasing to the eye. This comes in handy in the construction of residential buildings where homeowners are more interested in the visual appeal of their roofs. It also provides a unique selling point for contractors looking to stand out from their competitors.Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) has an experienced team of engineers and technicians who are always ready to provide technical support and installation services for the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine. The company's commitment to quality is evident in its use of top-quality raw materials and the strict quality control processes that go into every machine produced.In conclusion, if you're in the roofing industry and looking for a reliable and efficient way to manufacture high-quality PVC roofing tiles, the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is definitely worth considering. It is easy to operate, cost-effective, and produces tiles with excellent durability and strength. Contact Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) today to learn more about this amazing machine and how it can revolutionize your roofing business.

Latest Updates on W Beam Crash Barrier Roll Forming Machine: Breaking News and Key Insights

Title: A Revolutionary W Beam Crash Barrier Machine for Enhanced Road SafetyIntroduction:In an era where road safety is of paramount importance, the development and utilization of the W Beam Crash Barrier Machine have become crucial. Designed to withstand high-impact collisions and prevent vehicles from crossing into opposing lanes, this state-of-the-art machine is revolutionizing the road infrastructure sector. In this blog, we will delve into the concept, manufacturing process, and several benefits of the W Beam Crash Barrier Machine, ensuring safer roads for all.Understanding the W Beam Crash Barrier Machine:The W Beam Crash Barrier Machine is a cutting-edge roll forming machine that plays a vital role in manufacturing W-shaped steel beams, popularly known as W beams. These beams serve as a protective barrier on highways and roads, significantly reducing the risk of fatal accidents. The machine features advanced technology, enabling precise and efficient production of the barriers to meet international safety standards.Manufacturing Process:The manufacturing process of the W Beam Crash Barrier Machine involves several crucial steps. Firstly, high-quality galvanized steel strips are selected for their superior strength and durability. These strips are then fed into the roll forming machine, which shapes them into the distinctive W beam profile.The machine's advanced automation system ensures accurate dimensions and consistent quality during the roll forming process. After the beams are formed, they undergo prompt and reliable galvanization. The galvanizing treatment protects the beams from corrosion caused by harsh weather conditions, thereby extending their lifespan.Advantages of the W Beam Crash Barrier Machine:1. Enhanced Road Safety: The primary purpose of the W Beam Crash Barrier Machine is to create crash barriers that offer robust protection for drivers and passengers. The sturdy W-shaped beams ensure the containment of vehicles, minimizing the chance of crossover accidents and promoting overall road safety.2. Durability and Longevity: The utilization of high-quality galvanized steel strips and effective galvanization techniques equips W beams with exceptional durability. These barriers can withstand high-impact collisions and harsh weather conditions, reducing the need for frequent replacements or maintenance.3. Cost-Effectiveness: The W Beam Crash Barrier Machine optimizes production efficiency, resulting in reduced manufacturing costs. Additionally, the long lifespan of the W beams translates into cost savings by minimizing repair expenses and replacement needs.4. Regulatory Compliance: The W Beam Crash Barrier Machine aligns with international safety standards, ensuring that the produced W beams meet all necessary regulatory guidelines. This compliance provides peace of mind for road authorities and enhances the overall road infrastructure.5. Versatility: The machine can be easily adjusted to produce W beams of various shapes, sizes, and specifications, making it adaptable to different road infrastructure requirements. This versatility makes the machine invaluable for road authorities and construction companies.Conclusion:In conclusion, the W Beam Crash Barrier Machine represents a significant advancement in road safety measures. Its ability to manufacture durable, high-quality crash barriers ensures the protection of drivers, passengers, and road infrastructure alike. By promoting containment and minimizing crossover accidents, these machines have revolutionized the road construction sector. With their exceptional versatility and regulatory compliance, it is evident that the W Beam Crash Barrier Machine will continue to play a vital role in enhancing road safety worldwide.Keywords: W Beam Crash Barrier Machine, road safety, roll forming machine, manufacturing process, highway barriers, galvanization, durability, longevity, cost-effectiveness, regulatory compliance, versatility.

Roll Forming Machine for Creating Corrugated Galvanized Steel Roofing

Title: Corrugated Metal Roll Forming Machine: Revolutionizing Modern Roofing SolutionsIntroduction:As the construction industry continues to evolve, it is essential to embrace cutting-edge technologies that enhance efficiency and productivity. One such innovation that has revolutionized the roofing industry is the Corrugated Metal Roll Forming Machine. Specifically designed for producing corrugated galvanized steel, this advanced machine has become indispensable for manufacturers, delivering top-quality metal roofing solutions. In this blog post, we will delve deeper into the benefits and significance of the Corrugated Metal Roll Forming Machine in the modern construction landscape.Exploring the Corrugated Metal Roll Forming Machine:1. Enhanced productivity and efficiency:The Corrugated Metal Roll Forming Machine offers unmatched precision and speed, eliminating wastage and reducing production time. With its automated processes and cutting-edge design, manufacturers can produce more roofing sheets in a shorter span of time, resulting in increased productivity.2. Superior quality products:Equipped with state-of-the-art technology, the Corrugated Metal Roll Forming Machine ensures impeccable finishes and consistent corrugation patterns. This reliability guarantees high-quality roofing solutions that meet and exceed industry standards. The machine's ability to roll galvanized, pre-painted, and galvalume steels into corrugated galvanized steel ensures durability and longevity for the roofs.3. Flexibility in design:Corrugated roofing comes in various shapes, sizes, and profiles. With a versatile Corrugated Metal Roll Forming Machine at their disposal, manufacturers have the freedom to create tailored roofing solutions to cater to diverse customer needs. This adaptability allows for unique designs, providing architects and homeowners with extensive choices for their projects.4. Cost-effective solution:The Corrugated Metal Roll Forming Machine optimizes material usage and minimizes wastage, resulting in cost-effective manufacturing. Its highly efficient processes drastically reduce labor costs and turnaround times, making it an ideal choice for both large-scale production facilities and smaller roofing businesses. The savings accumulated through the use of this machine can be passed on to customers, making metal roofing a more economical option.5. Environmentally friendly:In the era of sustainability, the Corrugated Metal Roll Forming Machine has become a vital player in eco-friendly construction practices. By minimizing the excess material generated during the manufacturing process, this machine contributes to reducing waste and conserving resources. Furthermore, the durability and recyclability of corrugated galvanized steel roofing make it an environmentally conscious choice for builders and homeowners.Keywords and SEO:To maximize the search engine optimization (SEO) of this blog, it is crucial to incorporate relevant keywords ensuring the content aligns with search engine algorithms. By including words such as "corrugated metal roll forming machine," "corrugated metal roofing," "galvanized steel," and "roll forming," we can enhance the visibility of this blog post to the target audience actively searching for information related to metal roofing machinery.Conclusion:The Corrugated Metal Roll Forming Machine has emerged as a game-changer in the roofing industry, providing remarkable benefits such as enhanced productivity, superior quality products, design flexibility, cost-effectiveness, and environmental sustainability. By harnessing the power of this advanced machinery, manufacturers can meet the growing demand for modern, durable, and visually appealing metal roofs. As the construction industry continues to advance, embracing cutting-edge technology like the Corrugated Metal Roll Forming Machine is essential for the success and growth of businesses in the industry.